Contact us

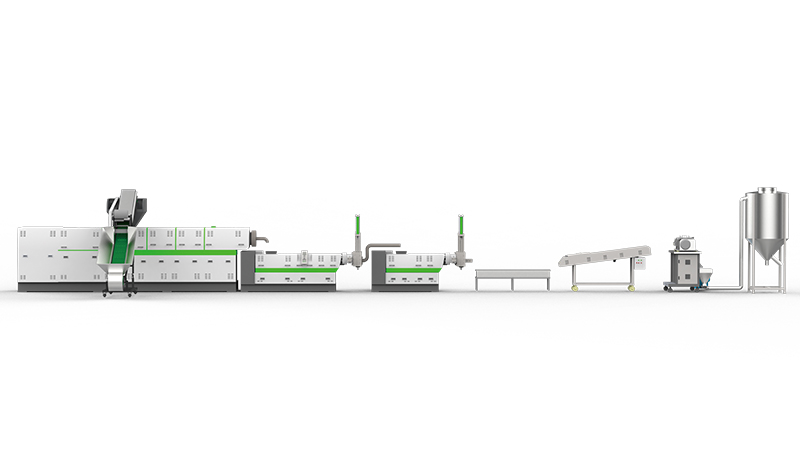

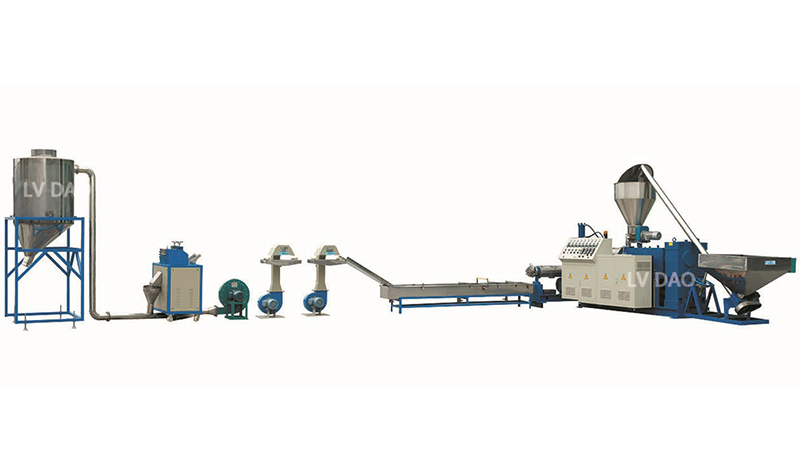

The plastic agglomerator produced by Yuyao Ludao Rubber […]

The plastic agglomerator produced by Yuyao Ludao Rubber and Plastic Machinery Equipment Co., Ltd. is used for film recycling and pre-granulation processing. The granulator is to put the label paper, plastic steel sawdust, medical gloves, agricultural film mulch chemical fiber, sofa film, etc. directly into the pot to smash. When it reaches a certain temperature, it will be granulated by pouring cold water. This is a convenient granulator.

The main functions of the agglomerator are:

1. The plastic pellet machine treats various soft plastic films, bags, silk, belts, sheets, sofa films, pipe wastes such as polyvinyl chloride, polypropylene, low-density polyethylene, high-density polyethylene, linear low-density polyethylene, etc. Recycling and scraps are put into production. Features of plastic agglomerator:

2. Plastic agglomerator for recycling and reproducing degraded plastic film and corner material by crushing and granulating. The plastic agglomerator crushes and granulates chemical fiber materials (polyester, acrylic, polypropylene, etc.), and puts them into the waste silk processing for reproduction.

3. The plastic agglomerator can be used for multiple purposes in one machine, which can replace mixers or dryers.

The working process of the agglomerator: After the waste is put into the pot of the machine, the material is quickly cut into pieces by the shearing action of the high-speed rotating blade and the fixed blade

, The shredded material or piece flows along the inner wall of the pot under the centrifugal force of the rotary cutter disk, and the material is turned up and down under the action of the slurry at the same time.

Moving from the periphery to the center of the pot body, due to the friction between the material itself and the friction with the pot wall and the blade at high speed, a large amount of frictional heat is generated.

Make the temperature of the material rise rapidly to reach a semi-plasticized state, and adhere to each other into small pieces, before the material is about to agglomerate,

The machine automatically sprays water into the material. When cold water encounters hot material, it quickly vaporizes and takes away the surface heat of the material.

In this way, the surface of the material is cooled rapidly to prevent agglomeration, and then it is shredded into particles by the crushing action between the rotating blade and the fixed blade

(Irregular pellets of irregular size). In the shredding process, you can also add appropriate pigments for coloring as needed.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3