Contact us

In recent years, with the rapid development of my count […]

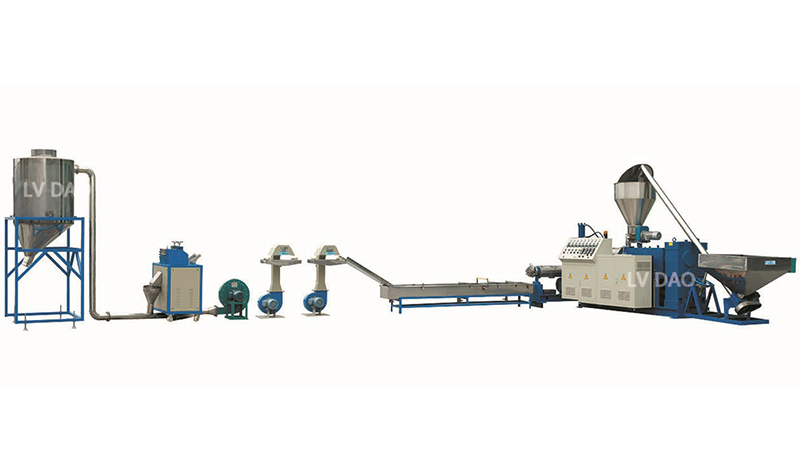

In recent years, with the rapid development of my country's plastics industry, the plastic granulator industry has also developed rapidly. The pelletizer can make recycled plastic products into plastic pellets through various processes to achieve the effect of plastic recycling. The granulator industry involves many areas of the national economy. It is not only an indispensable basic production link for a large number of industrial and agricultural products, but also plays an important role in solving China's plastic pollution, increasing the recycling rate of plastic products, and establishing a perfect plastic recycling system.

For recycled plastics companies, how to choose a pelletizer suitable for their own use is very important, because a plastic pelletizer cannot produce all plastics due to different plasticization and extrusion pressures. General granulators can recycle and granulate plastics in daily life, but like some special plastics, such as engineering plastics, composite polyethylene, spun yarn, etc., special granulators are needed for recycling and granulation. Therefore, manufacturers must pay attention to the types of plastics they need to recycle when purchasing a pelletizer, and then choose a suitable pelletizer.

In addition, when purchasing a granulator, you need to pay attention to the following points:

Clarify the type, purpose and voltage of the plastics that should be purchased for the production of the pelletizer. At present, there are roughly three types of customers who buy granulators in the market. They are invested and started by individual or private enterprises. Plastic manufacturers buy granulators to solve the problem of leftovers in their own factories. Then there are distributors and trading merchants. For customers of individual or private enterprise entrepreneurs, when purchasing a pelletizer, they must clarify the type of plastic the company produces. General pelletizers can only recycle and produce general-purpose plastics based on PP and PE, which are also common plastic raw materials in the plastics market. The PS foam material market is relatively small. If there is a clear sales channel for special plastics, users can also purchase corresponding pelletizers.

The performance of the granulator. According to the number of screws, the granulator can be divided into a single-screw granulator and a twin-screw granulator. When the single-screw granulator is working, the plastic is conveyed forward in a spiral in the barrel. When the twin-screw granulator is working, the plastic is conveyed forward in a straight line in the barrel. According to the working principle, when the twin-screw machine is stopped, the material in the machine can be basically emptied, and the single-screw machine can store a small amount of residual material. Most plastics can be pelletized, and the single- and twin-screw can be used indiscriminately.

However, when making recycled plastics, due to the larger surface of the screen changing die and easier blanking, the single-screw machine is more effective; when making modified plastics, color masterbatches, and mixed color pumping, the effects of the two machines are equally good. ; When making lengthened glass fiber and cross-linked submarine cable materials, only twin-screw granulators can be used. In addition, in terms of machinery purchase costs and later production costs, single-screw granulation opportunities are much lower, while twin-screw granulators are at a significant disadvantage. Therefore, when purchasing equipment, you need to select the corresponding equipment according to the different products produced by the enterprise.

The above is a simple sort of content that needs to be paid attention to when buying a granulator, for reference only. In addition, the technical parameters of the granulator, stability, reliability, safety and service life, degree of automation, energy saving and environmental protection, production cost, production efficiency, supplier and operability are all required when purchasing the granulator. Note the content.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3