Contact us

Whether you are producing plastic scraps or usin […]

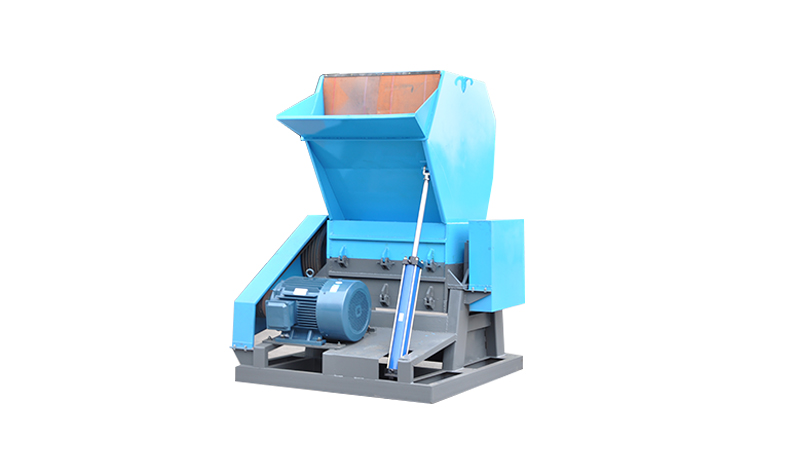

Whether you are producing plastic scraps or using the plastics during injection molding process, you need a plastic crusher to help you reduce the waste. These plastic crushing machines can crush almost all types of plastic materials. They are quiet, energy-efficient, and low-noise. They are suitable for a variety of applications and offer a range of rotor sizes. Some of these machines are specially designed for recycling plastic bottles, film, and PVC pipes.

Some plastic recycling grinders can granulate more materials. They are equipped with anti-wear plates in the crushing cavity, and heavy duty bearings that can absorb crushing impacts. They are also designed to withstand vibrations. They can also be used to shred plastics into fine particles.

In order to reduce the dust generated during the crushing process, the rotors are designed with a V-shaped angle. This can achieve better cutting and lower energy consumption. The rotors can be changed in order to produce regrind that is uniform in size. The regrind can also be pneumatically conveyed.

The series plastic crusher is specially designed for recycling PET bottles. It is a low-energy, high-output plastic crushing machine. It is suitable for recycling PET bottles, plastic film, and small hollow bottles. It has four different rotors that are tailored to different applications. The blades provides high abrasion resistance. Its body is made of a special high strength welded steel, which prevents excessive stress damage.

The plastic crusher is a plastic grinding machine. It can grind long plastic profiles, such as door panels, and small-dia plastic pipes. It is equipped with a dust removal system and a storage bin. It also has a suction fan.

Xiecheng's standard plastic crusher is a powerful plastic crushing machine, which can crush all kinds of plastics. The standard plastic crusher is available in four types: flat type, V-type, double-shear V-shaped cutting, and multi-shear V-shaped cutting. It can crush plastics that are soft and hard. It also can crush plastics with high fiber content. It is available in rotor sizes from 300 to 1500mm. The machine is also available in soundproof design to meet higher requirements.

Plastic crusher blades are made of high-strength alloy tool steel and vacuum quenching heating treatment. They are durable, and can crush soft and hard plastics. The blades are produced by drilling, rough grinding, and milling machines. They are designed to minimise wear, thus extending the lifespan of the plastic crusher.

series economical crushing machines have a special cutting technology to recover small hollow materials. They have heavy-duty rotor bearings to absorb the impact of the crushing process, as well as large rotor bearings to provide a strong crushing force. They also have a solid crushing cavity, allowing them to meet the demands of high-output and heavy-duty applications.

series plastic crushers are suitable for a variety of applications. They can be used to recycle injection mold parts, injection molding parts, film, PVC pipes, and plastic profiles.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3