Contact us

High Frequency Dewatering Equipment, a Multi-Frequency […]

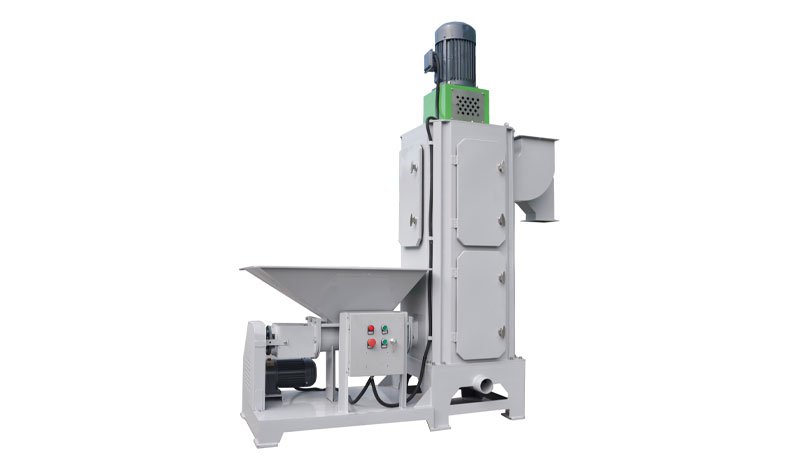

High Frequency Dewatering Equipment, a Multi-Frequency Gravity Generator, is a new high efficiency dispensing screen. Its primary function is to collect, isolate, and dispose of water from the aquifer. It is made of durable galvanized steel. It has no moving parts and can be easily cleaned. It is suitable for most well-holes, regardless of their depth.

The manufacturer supplies the machine, the equipment repairman, and the appropriate service for installation and repair. Installation and repair are carried out by suppliers, who are usually professional industrial repairmen. Installation takes about three hours, while repair takes longer. Service usually takes place at the manufacturer's plant or at the customer's location.

The High Efficiency Fibre Pooling (H.E.F.P) filter press machine consists of four primary components: the tank, motor, roller, and the cover. The tank holds the solution that is recovered during the water filtration process. A pump moves water through the tank and a cover prevents the water and waste products from flowing into the drainage pipes. The pump also supplies power to the filter press and the motor turns the motor and the belt filter belts.

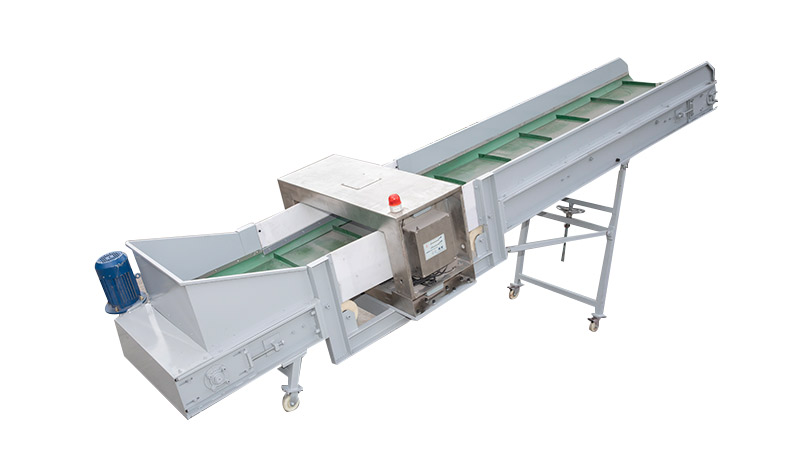

The high efficiency fibre filter press membrane filter press machine is a large-sized equipment that needs a dedicated electrical supply. It has single or double phase high efficiency multi block roller. The roller forces the dirty water through the fine mesh filter where it is collected. The clean water flows into the chute and then to the tank through the single or double phase belt drive. The chute can be manual or automated depending on the type of machine and model.

The High Efficiency Fibre Pooling (H.E.F.P.) filter press is easy to use. This type of machine uses the principle of electrostatic attraction and the result is extremely efficient dewatering. It is one of the two types of electrostatic dewatering manufacturer in the market. This manufacturer has been able to improve the efficiency of the H.E.F.P. by using the electrostatic control method.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3