Contact us

Plastic waste has become a global environmental crisis, […]

Plastic waste has become a global environmental crisis, with mountains of discarded plastic polluting landfills, oceans, and even remote areas. Finding effective solutions to address this problem has become a pressing need for our society. One potential solution that has gained attention is the plastic mixer machine. But is it truly the answer to our plastic waste problem? This essay aims to explore the capabilities and potential impacts of plastic mixer machines in order to answer this crucial question.

What is a Plastic Mixer Machine?

A plastic mixer machine is a mechanical device designed to process and recycle plastic waste. It operates by taking various types of plastic, such as PET bottles, HDPE containers, and PVC pipes, and combines them through a heating and mixing process. The resulting mixture can then be molded into new plastic products or used as raw material for manufacturing processes.

Capabilities of Plastic Mixer Machines:

Plastic mixer machines have several capabilities that make them attractive in the context of plastic waste management. Firstly, they can process a wide range of plastic materials, allowing for the recycling of diverse types of plastic waste. This versatility is crucial as plastic waste often consists of various polymers and grades. Secondly, the heating and mixing process employed by these machines can efficiently break down plastics, reducing them to a homogeneous mixture. This promotes easier processing and enhances the quality of the recycled material. Lastly, plastic mixer machines can contribute to the circular economy by transforming plastic waste into valuable resources, reducing the dependence on virgin plastics and minimizing environmental harm.

Potential Impacts:

The adoption of plastic mixer machines could have far-reaching impacts on our environment, economy, and society. By diverting plastic waste from landfills and oceans, these machines could help reduce pollution and conserve natural resources. The recycled plastic material can be used to manufacture new products, fostering a more sustainable and circular economy. Furthermore, the presence of plastic mixer machines in communities may raise awareness about plastic waste issues, encouraging individuals and businesses to adopt more responsible plastic consumption habits. However, it is essential to consider the potential environmental footprint of these machines, including their energy consumption and emissions during operation.

Plastic mixer machines have the potential to play a significant role in addressing our plastic waste problem. Their ability to efficiently process and recycle various types of plastic waste holds promise for reducing pollution and promoting a circular economy. However, it is crucial to address the limitations of these machines, such as the need for proper sorting and preprocessing, their compatibility with different plastic types, and the cost considerations. Ultimately, the adoption and success of plastic mixer machines will require a comprehensive approach that includes proper waste management infrastructure, public awareness campaigns, and government support. Only by combining these efforts can we hope to find sustainable solutions to our plastic waste problem.

LOW SPEED COLORING AND MIXING MACHINE

It's used for the coloring and mixing with the low speed. Cubic: 25-200L.

1.Designed with four-wheel vertical type,which is small in size and convenient for moving.

2.No over-temperature protection, overload protection, multiple safety protection.Dual digital display directly measured temperature and design temperature.Helical circular mixture,material can be mixed evenly within short period of time with high efficiency and low energy consumption.The timer may be chosen within 0-30 minutes for mixing.

3.Start automatically delay the opening of the electric power off automatic delay off the fan.Touch the light control automatically start a key.configure the exhaust filter to reduce pressure loss to prevent dust flying to protect the factory environment.

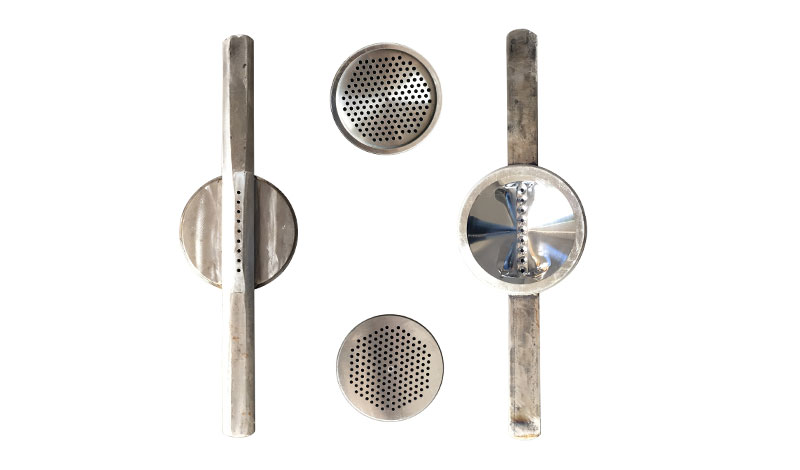

4.Stainless steel blades are scientific and reasonable in structure,which may mix materials evenly during operation and minimize workload while saving time and power.It is made of fine stainless steel with high intensity and may be washed conveniently.

5.Suitable for all kind of plastic raw material and color mixing,virgin,regrind and Masterbatch mixture will have effective result.

6.The mixer rotary speed is 68r/min,it can mix the crushed material or particles.It has five models.Its maximum mixing capacity is 300L, and its minimum capacity is 50L. Its maximum power is 10kw, and its minimum power is 1.5kw.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3