Contact us

Plastic Crusher is a machine that crushes various forms […]

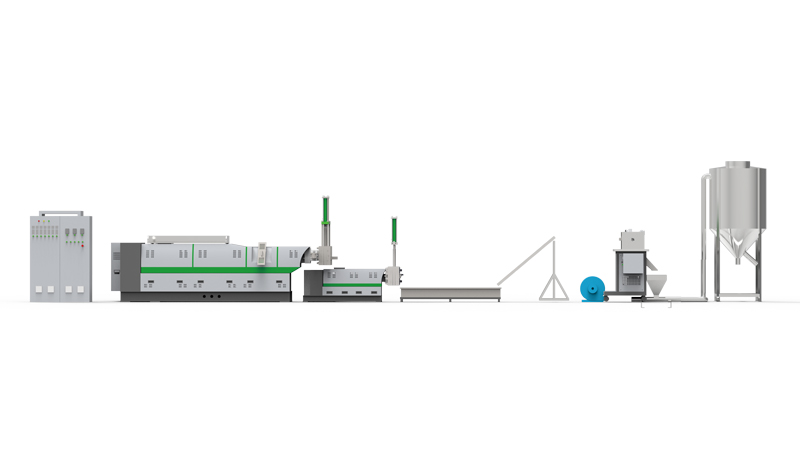

Plastic Crusher is a machine that crushes various forms of plastic material into small granules of various size. Crushed plastic can then be reused for further reproduction of plastic items. This machine helps to reduce the amount of plastic waste, highly save costs and resources, and increase the productivity of various manufacturing industries. Plastic Crusher is one of the most significant innovations of Filmmaster.

Plastic Crusher is a heavy duty machine, equipped with huge water drum. Water is pumped in through water drums, while attached to a huge drum roller. In this process, heat from the water drum is generated and transferred to the plastic grains. The plastic grains become soft and flexible, while getting crushed into fine particles.

Plastic Crusher machine is an advanced type of filtration unit. It can process a large volume of plastic, as compared to a single pe film filtration machine. A single pe film filter is found to have a limitation on the amount of plastic that can be processed, in terms of the size of the mesh. But, a Plastic Crusher machine, connected to a large water drum and a pet bottle crusher, can process thousands of pieces of plastic, in a short span of time.

Plastic Crusher is an important device for all sorts of industries, including Plastic Bottle Crushers, Plastic Shredders, Plastic Mixers, Plastic Crusher and so on. Plastic crushers, shredders, cutters, extractors, tank mixers, tank crakers, etc. are some of the manufacturing equipment, which help to manufacture plastic products. Lvdao is one of the professional manufacturer of plastic crusher in China, over 20 years.

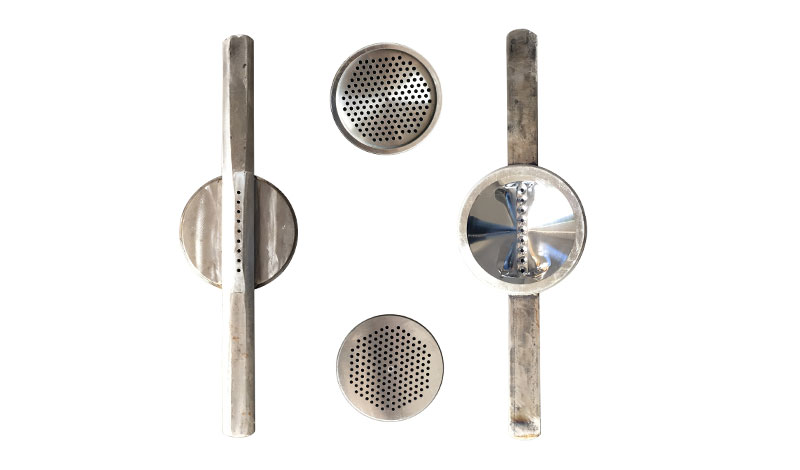

In the context of Plastic Crusher, we have a Petite Plastic Crusher, which is ideal for breaking small holes, for example in plastic bottles. These are available in stainless steel too. These crushes the small particles, which are present inside the plastic bottles. The Petite Plastic Crusher, when operated with the help of manual or automatic switch, melts the plastic film on the surface of the plastic bottle and releases the air pressure inside. This releases the trapped particles, which helps in removing them from the surface of the bottle.

Another important thing about these Plastic Crusher, is that they are highly durable and long life. As the Plastic Crusher is run by electricity, it does not need much maintenance. As the blades move in the vertical direction, the blades play an important role in removing large particles. If the blade does not move in the same direction constantly, then there are chances that the particles will be dislodged from the surface of the plastic products. Therefore, if you have a large production of plastic products, then the blades should work in the same direction to increase the efficiency of the crushers.

This Plastic Crusher machine has a light weight, compact and robust construction. If you want you can even adjust the machine accordingly according to the power and also depending on the speed. The rate at which the Plastic Crusher stops and starts functioning varies according to the speed and the kind of particles that are being crushed. Most of these Plastic Crusher machines are powered by the engine of the car. However, if the engine of the car is not strong enough to power the Plastic Crusher, then you can opt for a battery operated Plastic Crusher.

In general, the rate at which the Plastic Crusher melts the plastic product is about 95 %. All types of Plastic Crusher come in different sizes, which depends on the thickness of the plastic product that is to be crushed. The best quality Plastic Crusher should be made up of a very strong structure. If it is possible, you should opt for a Plastic Crusher with a size of size as well as with steel material. If you can find a machine with a size mm and a steel material combination, then you would definitely get more power to crush the plastic products without any difficulty.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3