Contact us

Using a waste plastic recycling machine helps yo […]

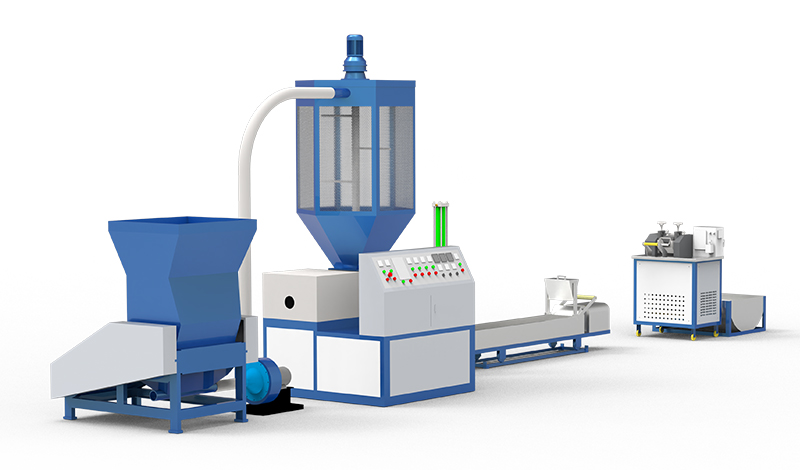

Using a waste plastic recycling machine helps you save money, time, and energy. It is also a more environmentally friendly method for recycling plastic. Moreover, it can reduce your storage and labor costs. The machine is easy to use and can break down plastic into smaller pieces. This type of equipment is a perfect solution for the circular economy.

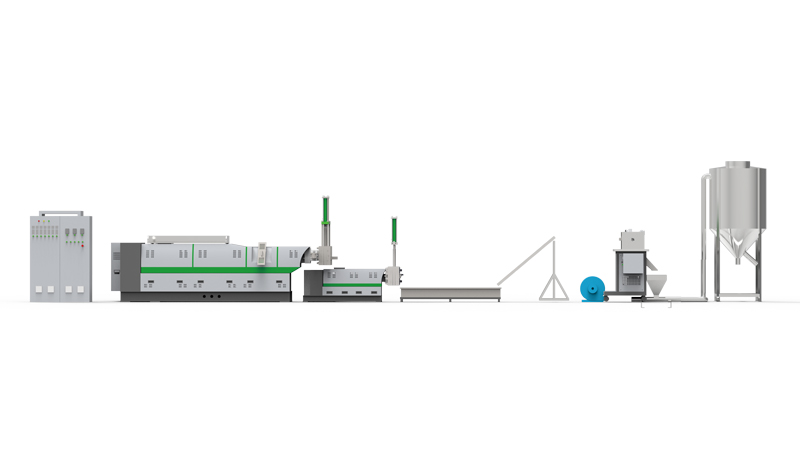

The basic process of plastic recycling involves collecting, sorting, and purifying the material. It is then reshaped into pellets, which can then be re-purposed for use in new products. Most plastic recycling processes involve pelletizing and size reduction, allowing the reclaimed material to be distributed more easily.

Depending on the material being recycled, different separation processes may be used. The most common wet method uses float tanks. These tanks separate the material by density, sinking, or floating. This process is typically used for plastics that are soft, but not brittle, such as polypropylene.

A few recycling services can also be used to reclaim mixed plastics. However, most processes will require the material to be sorted. Failure to do so can cause inconsistencies in the properties of the reclaimed plastic and can lead to inconsistent products being produced. This can occur when the material is contaminated by organic contaminants.

Many types of plastic are not suitable for recycling due to their physical properties. This includes polystyrene, which is a very bulky material. It is also difficult to transport and is abrasive to metal blades. In some cases, it can be made into food-grade plastics.

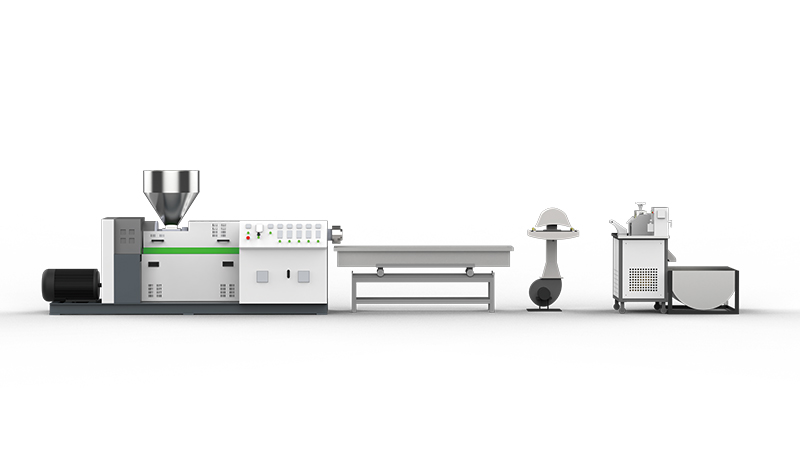

These systems can also be used to reclaim plastic from industrial waste. Arlington Plastics Machinery offers an extensive line of recycling equipment, including underwater pelletizers and strand pelletizers. It also offers a liquid ring pelletizer.

These machines are available from outputs of 40 kilograms per hour to 150 kilograms per hour. They are light and durable, making them ideal for the circular economy. They have many benefits and are more in demand than ever. A recycling robot is being used by some plants in Europe. This automated device can sort up to 80 items per minute. It is used for plastics and glass.

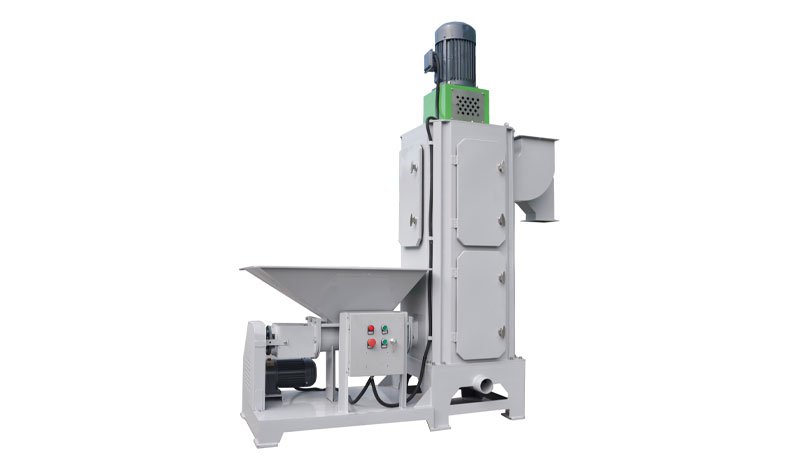

Plastics are becoming more and more complex. As a result, they need to be shredded into smaller sizes before they can be recycled. It is also important to keep in mind that different plastics have different properties, such as hardness, thickness, and weight. It can also be difficult to separate the various components of the plastic.

Most plastic recycling machines work by shredding the waste and then processing the resulting granules. The granules are then heated, which makes them reshape. This is the final step in most plastic recycling processes. The reclaimed plastic is then melted and reshaped into pellets, which can be re-purposed for use in industrial manufacturing.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3