Contact us

A Belts Conveyor is an arrangement of rollers and pulle […]

A Belts Conveyor is an arrangement of rollers and pulleys, with a fixed closed loop to move materials through a system of pulleys and rollers. A Belt conveyor is used for all sorts of transportation, where the movement is controlled mechanically, either by direct physical action or indirectly by an operator. Belts conveyors can be used in a wide range of industrial applications, from packaging to manufacturing and conveyor systems have developed vastly over the years and continue to do so.

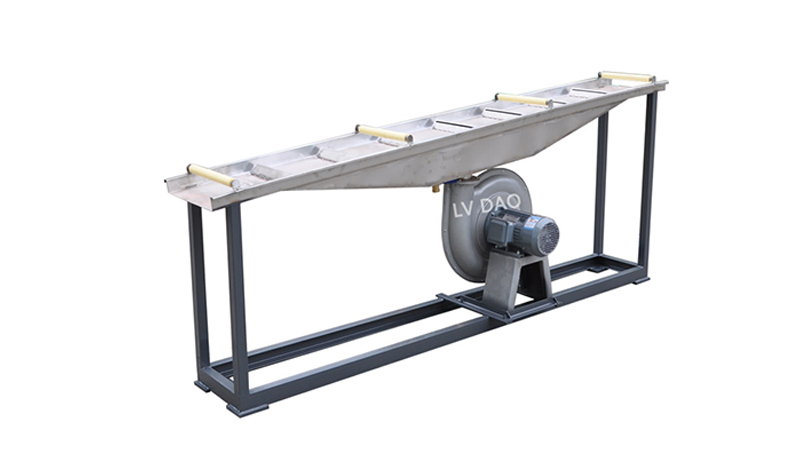

There are many types of Belt Conveyors, one type of which is the Single Slip Belt Conveyor, sometimes also known as a Multi-Slip Belt Conveyor or Multi Slip Chainless Belt Conveyor (which is similar). These types of conveyors are usually used in production environments where speed and efficiency are paramount. The benefits of using these types of conveyors over others include: Speed these conveyors are faster than chain conveyors, which make them ideal for tight spaces. Efficiency - due to the fact that belts convey goods without the bouncing problem and with a smoother movement, they are the most efficient conveyors. Due to their speed and design, these conveyors can also handle very heavy loads without any problems.

There are several types of Belts Conveyor systems available for different industries and business requirements. The most basic type of belt conveyor is the Single Slip Belt Conveyor, which is also known as a Single Chain Belt Conveyor. This is probably the most popular type of belting system and it is ideal for light duty use. However, there are also multi-chain belt conveyor systems that feature an extra parallel chain and a center main chain to assist in heavier goods and products.

Other advantages of using a Single Slip Belt Conveyor is that it offers speed with minimal strain on the machinery or truck. The system can easily detect the weight of the product and easily adjust the load distribution. They often feature roller or slide roller systems. Some belt conveyor systems have a built in safety switch that automatically shuts off the system when the pressure reaches a certain point. The safety switch is usually located in the handling section and can easily be accessed through safety stickers.

Another type of belting system is the Multi Slip Belt Conveyor System, which is more complex than the Single Slip Belt Conveyor. This multi-track conveyor system features roller belts, which are of varying widths and heights, and double chain loops. These allow the system to be able to detect the load and adjust the load distribution for different products. The standard size of multi-step belts are typically 18 inches wide, although they can be manufactured to your specifications.

Belts that use electric motors as part of their design are referred to as Direct Electric Belts. The electric motor turns on as the belt passes over it, which causes the belt to rotate. As the belt spins, a set of idler rollers is engaged and slows the conveyance. Idler rollers are typically made from either stainless steel or aluminum and are available in a variety of configurations.

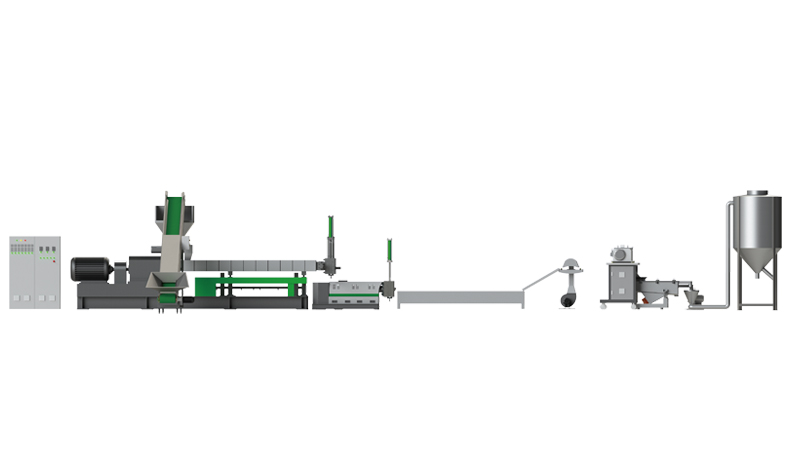

The third type of belting system is the Multi-layer Combination Belting System, which uses both types of conveyors to help increase speed and efficiency. This is the most complex of all three types of conveyor belts and typically requires skilled operators to operate. There are typically three layers to the Multi-layer Combination Belting System, consisting of an inner ring layer and two outer ring layers. As the belt moves over the inner ring layer, it breaks the former layer and applies new sheet metal. The new layer is smoother and generally has a higher tensile strength than any previous layer.

Each of these three types of belt conveyor systems is able to handle various loads; however, it is important to consider which system will be the best for your specific needs. If your business relies heavily on very heavy loads, then the Direct Electric Belts may be the better option, as they provide more strength and are typically easier to repair. However, if your business operates with smaller loads, a Multi-layer Combination Conveyor Belt might be the better option. If you are unsure which type of belt conveyor would be best for your needs, it is recommended that you speak with a qualified professional to assist you in making the correct decision.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3