Contact us

We will discuss the different types of PP film extricat […]

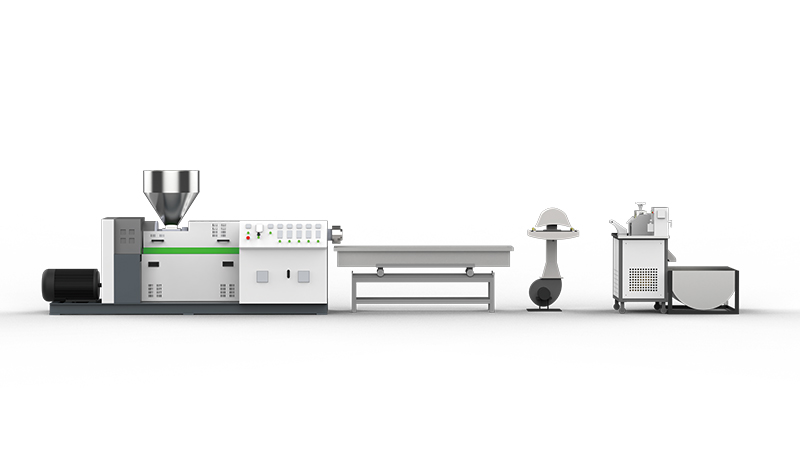

We will discuss the different types of PP film extrication equipment available in the market. The two types of equipment are - the belt pulley type and the plastic pelletizing line or the water ring type. These two types of extrication equipment have their own advantages and disadvantages. Let us discuss each type separately. This will help you decide which type would be best suitable for your business.

Belt pulley type: The belt pulley type is usually installed by the manufacturers as a part of the fluid bed assembly, where it functions as a pulley. Once it is connected, the operator moves the belt through the extruder where it comes in contact with the resin bed at the bottom of the drum. The plastic that is collected in the extruder is then collected by the granulating machine. If the number of coils in the pulley is greater than the number of drum in the line, then the collected solid material is collected in a separate container.

Plastic-film recycling equipment like the water ring plastic pelletizing line has the capacity to convert the collected solid material into plastic pellets. The plastic film is made of three parts - the liner, the outermost resin coating, and the remainder an anti-rot pigment that slows down the rate of formation of the plastics. This makes it possible to form plastics into different shapes and sizes, depending on what is required. The lining of the film is made of resins that are derived from crude oil and recycled rubber. It is pre-bonded with terephthalate and UV stabilizers to make it ideal for use in the recycling industry.

The lvdao water-ring plastic pelletizing line is used to recycle plastics like oil. The water-ring plastic pelletizing line can be found in most wastewater treatment centers, as well as municipal solid waste facilities. When the water-ring plastic pellets are inserted into the large conveyor belt, they are recycled. They are left in the conveyor belt for approximately twenty-four hours, where they make it through the water-ring plastic pelletizing line and into the final recycling container.

Single screw extruder line: This line produces high quality plastic by using only one screw for the connection of the resin and the metal. Unlike the water ring type, this line has no screen changer or cooling fan. The plastic is passed through the feed roller over the single screw and the melted plastic is collected in a separate container. This type of plastic pelletizing line can be used to manufacture pipes, tubes, hoses and other metal components that require low melting points during manufacturing. The high quality of the plastic produced by this line can be further enhanced by the addition of UV stabilizers and the application of an electrostatic charge to enhance the electrical conductivity of the plastic.

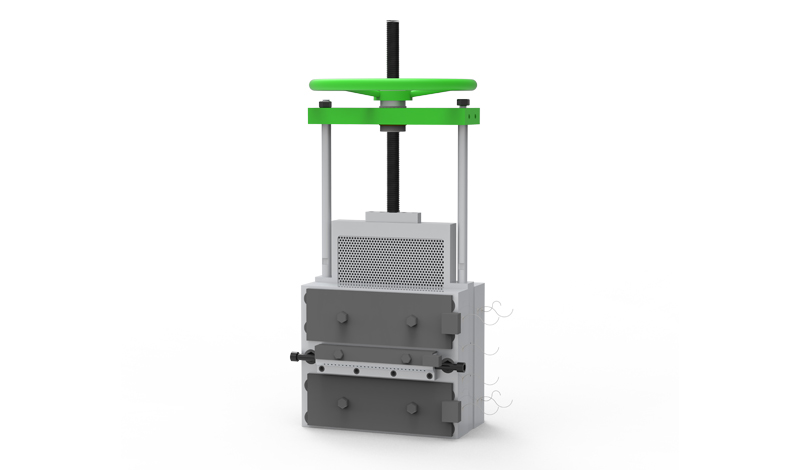

The dual roller extruder line: This plastic recycling machine has an extruder that features two rollers. This gives the manufacturer the ability to form plastics into round shapes as well as in different sizes. The dual roller extruder is commonly used in the manufacturing of pipes, tubes and the attachment of lids and other accessories to these items. It is ideal for applications where the plastic needs to be formed into a bowl shape, a cylindrical rod, or any other shape that can be rolled onto a roller.

The bottom line is that the proper plastic recycling machine that matches the requirements of your particular job should be selected. Not all machines are designed to yield the same quality of plastic. Only through experience and a great deal of testing will a manufacturer be able to determine which type of pelletized line is best suited for the application for which it is being used. Once the appropriate machine is found, the production efficiency of the business can then be improved significantly.

View Plastic Pelletizing line catalogue

Three most important benefits of investing in Lvdao Plastic Pelletizing Production Line

Dependability - An lvdao machinery can rely on reliable and efficient machinery and other modern technologies. It also relies mostly on reliable raw materials such as plastic pellets, resins, chemicals and many others. With such dependability, you can be assured that you will always get the best results every single time you produce plastic pellets and other kinds of plastic materials. Moreover, you can be sure that the plastic pelletizing production line will always be able to process a large amount of materials. This way, you can be assured that you can always be able to have supplies of whatever you need.

High Output - Pellets that are made out of plastic waste are not easy to process. They are usually thick and difficult to form and this is the main reason why only a large amount of plastics can be produced out of these. However, with a high output plastic pelletizing machine, you can be able to process more pellets in less time. This is very helpful for your business because it means you will be able to continuously produce more pellets.

Reliable Raw Material - It is no secret that any type of raw material would have to undergo a lot of processing before it can be turned into something useful. However, with any raw material, there will always be wastage. This is why it is important to have a high output plastic pelletizing machine. This way, you will be able to have raw materials that can be processed into useful pellets so you can make use of them in your business. After all, you cannot have profits if you are not making use of the raw material you have.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3