Contact us

A Hot Cutting Granulator is a machine that is used to p […]

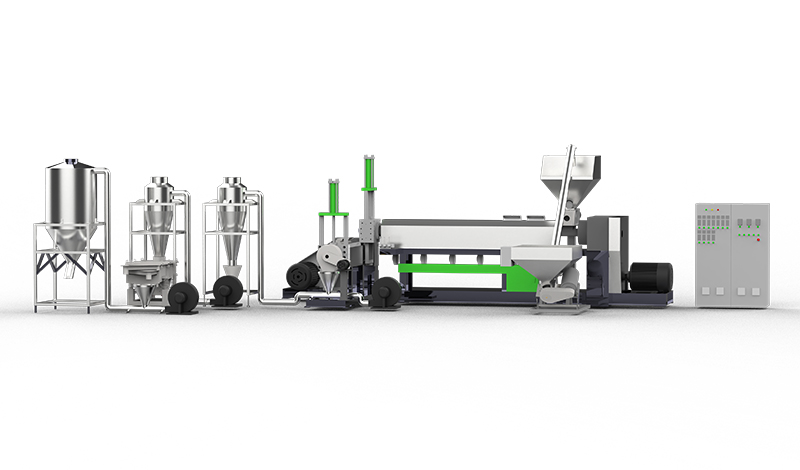

A Hot Cutting Granulator is a machine that is used to process plastic materials. It can be used to process HDPE and PVC waste films. The particles produced are uniform, dense, and beautiful. It is widely used in the field of plastic recycling, especially in the production of powders, plastic bottles, and other similar materials. A Hot Cutting Granulator produces a consistent size of particles, with a uniform shape and consistency.

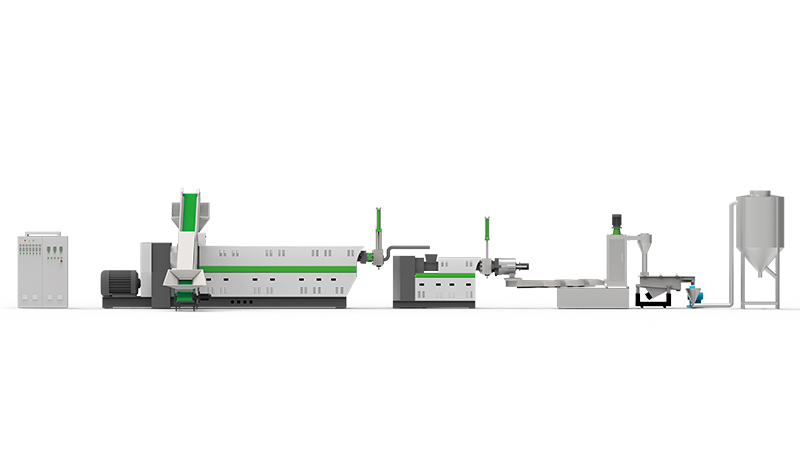

The hot cutting granulator has an efficient cooling system. Its modified Shurfeed cutting chamber is specifically designed for the recovery of hot plastics. A special air flow through the open rotor and expanded chamber area provides a fast cooling effect for the material. A scissors-cut blade configuration and uniform rotor-to-screen clearance deliver a high throughput for plastics. The two-stage heating and ventilation systems ensure a uniform temperature across the entire granulation chamber.

Our Hot Melt Granulator uses a modified Shurfeed cutting chamber designed to recover hot plastics. The extrudate falls directly in front of rotating knives, where it undergoes the cutting action immediately. The rotor's open rotor area and evacuation blower create high volume air flow, which cools the material quickly. The scissors-cut blade configuration delivers a high positive throughput for plastics.

It consists of a plastic extruder, screen changer, and grinding surface eagerly cutting head. Its unique design allows it to withstand high temperatures and still maintain a constant rate of throughput. With its low energy consumption and high efficiency, the HMG Hot-Cutting Granulator is the ideal machine for manufacturers of plastic and cable products.

Hot Cut Granulator is a modified Shurfeed granulator that is designed for recovery of hot plastics. It is designed with an open rotor and high volume airflow through the rotor, which cools the material quickly and efficiently. Its scissors-cut blade configuration and uniform rotor-to-screen clearance provide positive throughput. It is the ideal machine for blending wood and PVC powder with filler and wood.

Hot Melt Granulators are designed with a modified Shurfeed cutting chamber for plastics. The rotor is designed to recover hot plastics from the hopper. The granulator uses a scissors-cut blade configuration, which is the best way to recover plastics from the furnace. The rotary cutter is a powerful tool for processing PVC-based materials. It is easy to operate and requires little maintenance.

The plastic granulator uses a special screw design and configuration to process waste plastics. It is particularly suitable for recycling agricultural waste plastics and industrial packaging films. It can also process PVC pellets with additives. Another type of granulator is the PVC granulator. A plastic granulator can be used to process a variety of waste plastic materials, including woven bags and film.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3