Contact us

Plastic Granule Cutters are instrumental in reducing wa […]

Plastic Granule Cutters are instrumental in reducing waste and conserving resources through various mechanisms and processes.

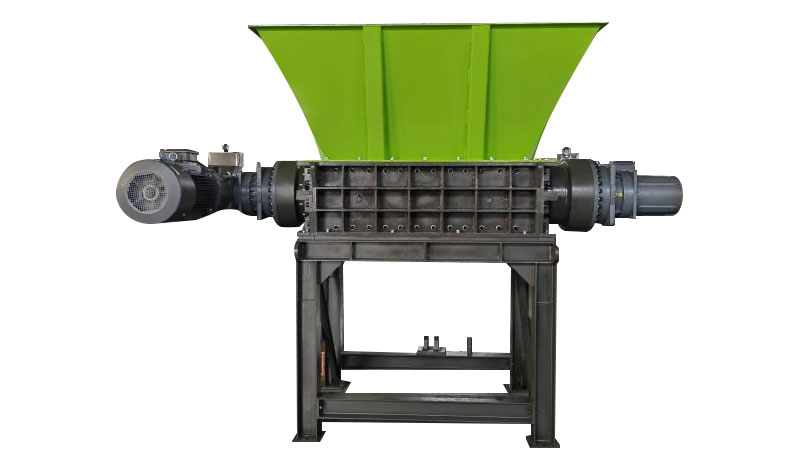

Efficient Size Reduction

Plastic Granule Cutters are designed to efficiently reduce the size of plastic materials, including large components and waste items. They achieve this by using sharp blades, shredding mechanisms, or granulation processes. By breaking down oversized plastic objects into smaller, more manageable granules, these machines help prevent valuable plastic materials from being discarded as waste.

Recycling Facilitation

One of the primary ways Plastic Granule Cutters reduce waste is by preparing plastic waste for recycling. Large plastic items, such as containers, automotive parts, or industrial components, often cannot be processed directly at recycling facilities due to their size and shape. Plastic Granule Cutters transform these bulky items into granules that are easier to clean, sort, and process. This step is crucial in streamlining the recycling process, making it more cost-effective and resource-efficient.

Circular Economy Promotion

Plastic Granule Cutters play a pivotal role in promoting the concept of a circular economy, where materials are reused and recycled rather than disposed of as waste. By turning plastic waste into granules that can be used as feedstock for new plastic products, these machines contribute to closing the loop in plastic production and consumption. This reduces the demand for virgin plastic materials, conserving the raw materials used in plastic production, such as petroleum-based polymers.

Waste Diversion from Landfills

Plastic waste is a significant contributor to landfills, taking up valuable space and posing environmental risks. Plastic Granule Cutters help divert plastic waste away from landfills by enabling recycling and repurposing. By reducing the volume of plastic waste sent to landfills, these machines contribute to more efficient landfill management and reduce the environmental impact associated with landfill disposal.

Energy Savings

Producing plastic from raw materials requires significant energy inputs, such as the extraction and processing of petroleum-based feedstocks and the energy-intensive manufacturing processes. By recycling plastic and using Plastic Granule Cutters to prepare recycled materials, energy consumption is reduced. Recycled plastic typically requires less energy to process than virgin plastic, contributing to overall energy savings and resource conservation.

Reduced Environmental Pollution

Improper disposal of plastic waste, especially in marine environments, leads to environmental pollution and harm to wildlife. Plastic Granule Cutters play a vital role in mitigating this pollution by reducing the volume of plastic waste that ends up in oceans, rivers, and other ecosystems. This helps protect natural resources and biodiversity while conserving the integrity of aquatic and terrestrial ecosystems.

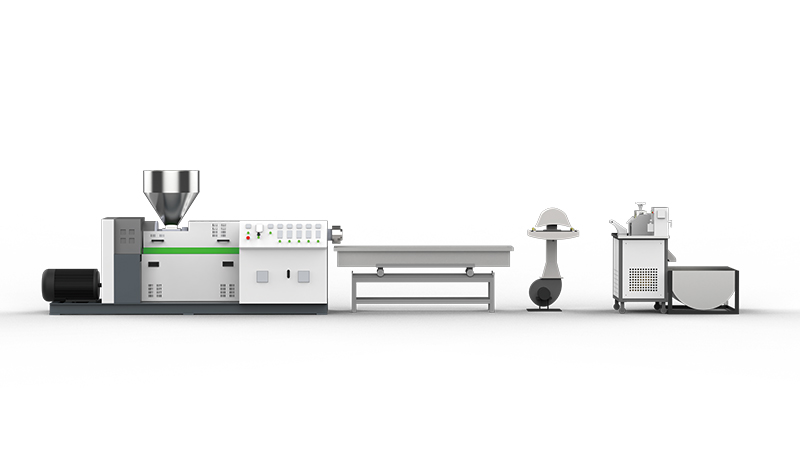

PLASTIC GRANULE CUTTER FPB-215

CAPACITY:400KG/H

Suitable for high capacity of pelletizing operation,using the domestic advanced technology concept, low noise, high stability.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3