Contact us

In the waste plastic recycling process, particle […]

In the waste plastic recycling process, particles of plastic are converted into usable materials. Plastic is either melted or crushed into pellets. Not all plastic recycling can be done at the same plant; different grades may be sent to different recycling facilities. Often, these plastics are then transported to various disposal sites. This article will explain both closed-loop and open-loop recycling. It will also explain what is meant by a waste plastic recycling machine factory.

Open-loop recycling

Open-loop recycling is the process of turning a single-use material into a completely different one. Oftentimes, plastic water bottles are recycled into fleece jackets or sleeping bags. These items undergo a continuous cycle, from manufacturing to usage to collection and recycling again. As a result, the recycled materials are no longer suitable for their original purpose, but can still be used in new products.

Closed-loop recycling

Currently, the company operates out of a Westside warehouse, and is raising funds to expand. The company aims to build a plant that is closer to polystyrene waste processing facilities. To date, it has a contract with Cold Canyon landfill to collect waste plastics, but it plans to expand.

PP

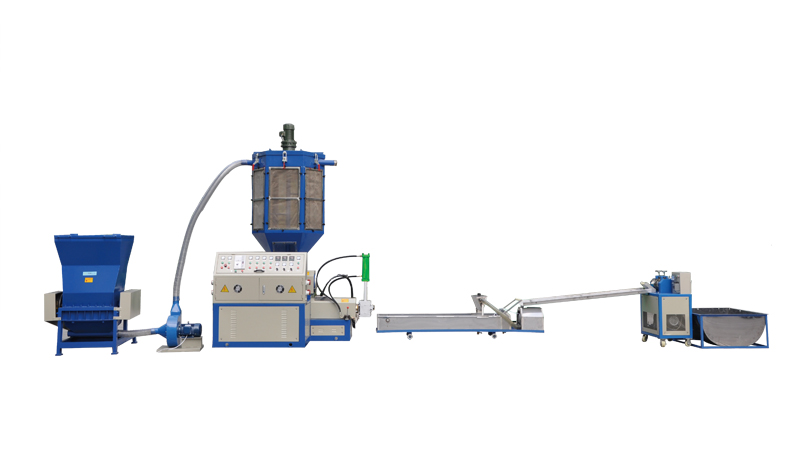

PP waste plastic recycling machine factory can process a wide range of PP waste materials, including post-industrial film, washed flakes, scraps, and rigid plastic. It is recommended for packaging film producers, such as manufacturers of commercial bags, agricultural film, food packaging, shrink films, and other plastics. Other materials that can be processed by this machine include PE foam, PE net, EVA, and PP mixed with PU. Ultimately, pellets from a PP waste plastic recycling machine factory can be used for production of various products, including automobile interior plastic, which is currently incinerated.

PS

A Waste plastic recycling machine is a type of plastic granulator used to recycle recycled plastic materials. These machines are ideal for recycling different types of waste plastic. These include film, PET bottles, cardboard, and even post consumer plastics. There are several different models available, but a typical machine can handle a wide variety of materials. In addition to PET bottles, you can recycle other types of plastics such as PE foam, EVA, and PP mixed with PU.

LDPE

In addition to being environmentally friendly, an LDPE waste plastic recycling machine can also save a great deal of power. The shredder is designed to reduce power consumption per kilogram, floor space occupancy, and operator attendance. This machine can also process various types of plastic materials directly, without pre-shredding. It can even process foamed plastics. Its versatility makes it an excellent choice for any plastics recycling factory.

LDPE-HDPE

An LDPE-HDPE waste plastic recycling plant is a valuable process for reprocessing scrap PLASTIC. The machines are capable of sorting the plastic into different polymers and chipping it into pellets. These pellets can be recycled again, and can then be made into plastic chairs, tables, and other products. These machines can even be used to make soft plastics such as trash bags.

HDPE

A HDPE waste plastic recycling machine factory is capable of converting this type of waste into useful products. In addition to plastics, HDPE also produces pollution in the form of sulphur oxides, particulate matter, nitrogen oxides, carbon monoxide, and water vapor. HDPE is responsible for a significant amount of air pollution as it emits pollutants such as sulphur, nitrogen, carbon monoxide, ammonia, and iron.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3