Contact us

Benefits of Plastic Granule Cutter Machines The Plastic […]

Benefits of Plastic Granule Cutter Machines

The Plastic Granule Cutter Machine is a common product used for industrial purposes. It can be used to cut plastic sheets and other materials into tiny pieces. The range of products made using this machine is extensive. Here are some examples of the applications of this equipment. Listed below are some of the benefits of Plastic Granule Cutter Machines. They are an excellent choice for a number of industrial applications. Let's learn more about this industrial machine.

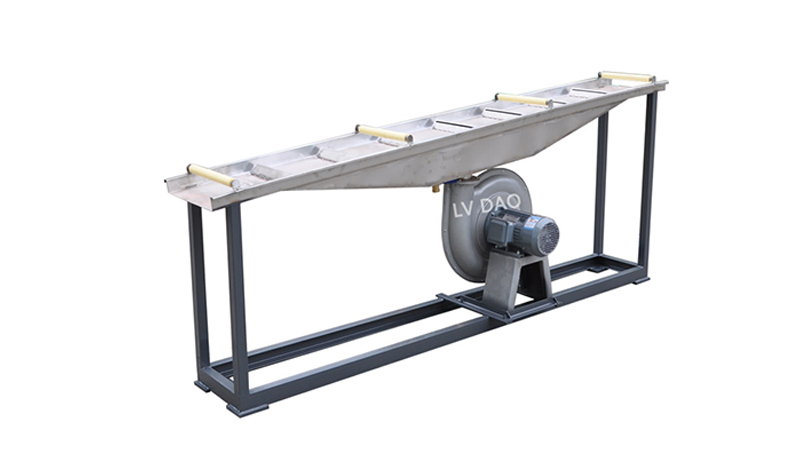

Rubber roller cutter

The rubber roller cutter for plastic granule cutter is a machine that is used to cut plastic granules. It uses a special process to coat the cutting rollers with a durable coating. This coating makes the machine durable even after repeated uses. It can also be used for cutting hard-to-cut materials, such as rubber. A rubber roller is not ideal for cutting hard-to-cut materials, but it does work well for plastic granules.

A plastic granule cutter comes in many varieties. Some models feed pellets into a hopper and spit them out. Before you purchase a plastic cutting machine, consider how much material you want to process. If you plan to recycle a lot of plastic, you will need a heavy-duty unit. For smaller amounts of material, a standard unit will do. The plastic granule cutter can cut small pellets, but if you plan to process large pieces of plastic, you'll need a large machine.

A heavy-duty plastic pellet cutter can make a ball every 60 seconds or more. It can handle high-volume plastic strips, such as granulated fertilizer. However, smaller models may take longer to finish a ball. In such cases, a compact model might be more suitable. The compact models are ideal for smaller operations. Nevertheless, they may take longer to finish one ball. A compact unit is also an excellent option, especially for small operations.

The stainless steel mesh 4 of the feed roller is designed to absorb and discharge forces in both directions. This is beneficial for the plastic material as it prevents the feed roller from causing deformation or groove formation. Further, the stainless steel mesh helps the feed roller absorb and discharge forces while preventing plastic strands from being displaced. Its rounded design also prevents the waste of plastic material. This allows the machine to work more efficiently and effectively.

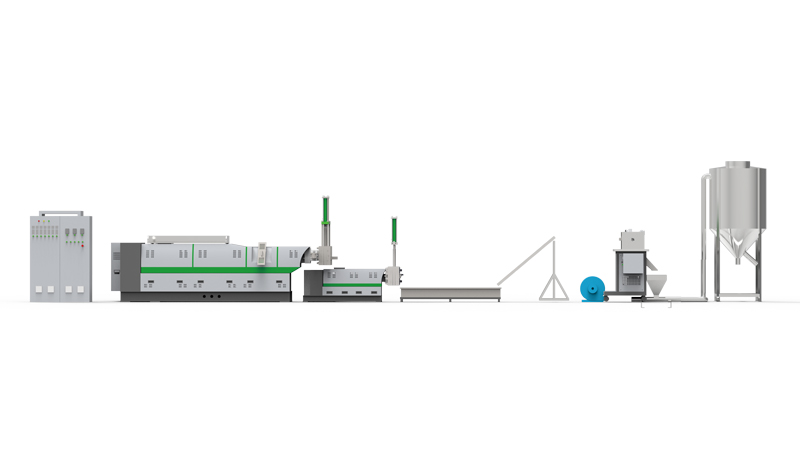

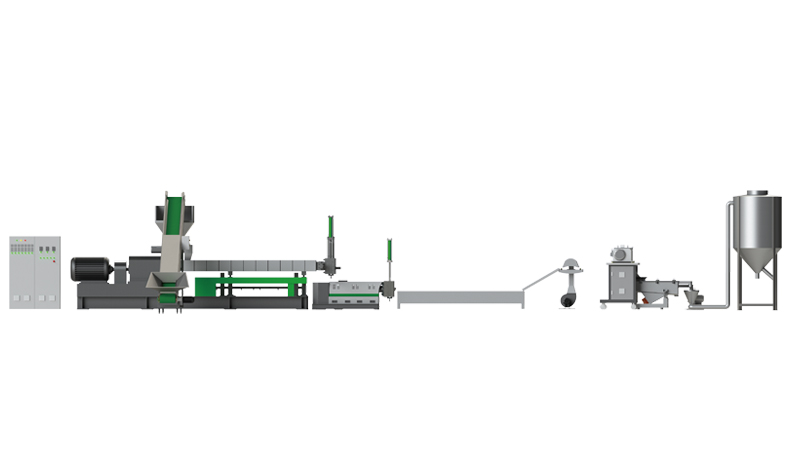

Spaghetti cutting system

A plastic granule cutter system is a very useful equipment for pasta production. It is highly suitable for high-melting-index plastics and materials. This cutting machine has a granulating die and a circulation box. In order to produce fine grains, the molten polymer is continuously extruded from the die's holes. The cutter blades are continuously rotating in the circulation box.

These extruders can produce all kinds of pasta, including lasagne, noodle, and spaghetti. They can also cut double sheets. The double sheets can be used to make two-color pasta, spaghetti with aromatic leaves, or spaghetti alla chitarra. There are models with automatic positioning and additional cutting units. It is highly recommended to have multiple cutting units installed on the same machine. This way, you can create more varieties of pasta, including ravioli, pappardelle, and spaghetti.

The granulation system includes a circulation box 109, a granulation die 106, and a control system 8 that automatically controls forward and backward pressure. The PCW is heated to a temperature of 69 deg C. to prevent pelletization trouble. The control system 8 also adjusts the position of the cutter blades 115 based on the temperature of the granule material.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3