Contact us

OEM Plastic Crusher OEM Plastic Crusher is a kind of cr […]

OEM Plastic Crusher

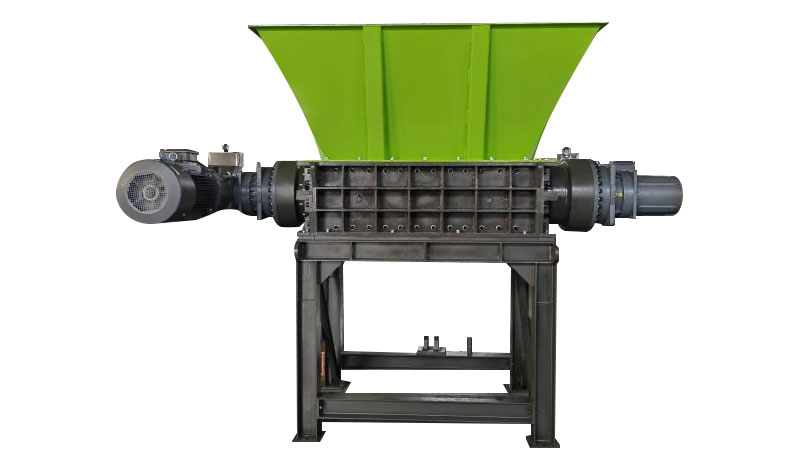

OEM Plastic Crusher is a kind of crushing machine that is used to crush plastic materials. It can be used to crush bottles, plastic films and other plastic materials. The crusher is designed with strong structure and low electricity consumption. It adopts high-quality steel blades that are ground repeatedly. The machine uses PLC control system to adjust its speed and adjust the feeding system. It can also be operated automatically. It can be set to work at different mesh size, material and voltage.

The upgraded design of plastic bottle crusher makes it possible to handle various types of plastic. The machine's rotors adopt a V-cut shape, which helps it cut the products more evenly and with less powder. Its base frame has rubber feet that reduce vibration and noise. The drive motor is mounted on tension rails for easy adjustment.

The WHC series heavy-duty crusher is designed to meet the requirements of different recycling industries, including waste plastic recycling. Its unique V-shaped crushing chamber design and feeding hopper allows it to work with various recycling production lines and washing and pelletizing lines. The main shaft of the machine has passed balance tests and can handle a wide range of plastic materials.

Advantages of the OEM Plastic Crusher Factory

OEM Plastic Crusher Factory can provide high-quality plastic crusher machines at competitive prices. Its advanced design can crush plastic products such as bottles and barrels easily and efficiently. Its rotary blades are set at an angled V shape, which ensures even granulations and less powdering. Its chamber is made of hard steel, which makes it durable and easy to maintain.

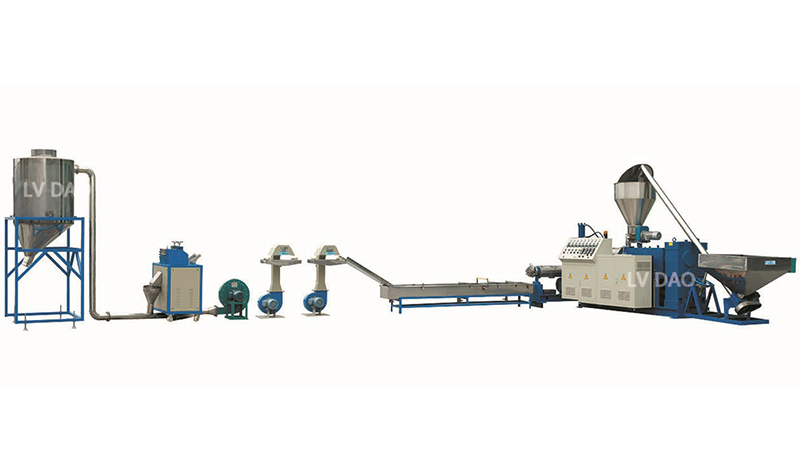

OEM Plastic Crusher Factory can recycle plastic scrap using knife technologies. Traditionally, plastic product OEMs have shipped scrap materials to recyclers in China or regional recyclers. Grinding the plastic into pellets allows them to reuse it, thus reducing input costs. However, the process of grinding, screening, and shredding to size requires separate processes. This can create a bottleneck in production.

Compared to other plastic crusher machines, the OEM Plastic Crusher Factory offers the following advantages: Easy operation, low electricity consumption, low noise, and a high capacity for crushing plastic products. It is also designed to meet the safety regulations of Europe. Besides, it is able to crush various types of plastic, including soft and hard plastic.

This industrial plastic crusher uses high-quality steel knives and high-strength screws. It is also noise-free, thanks to the noise reduction system. The movable screen, which can be cleaned easily, helps reduce the noise pollution. It also features a heat-conduction system to extend the motor's life.

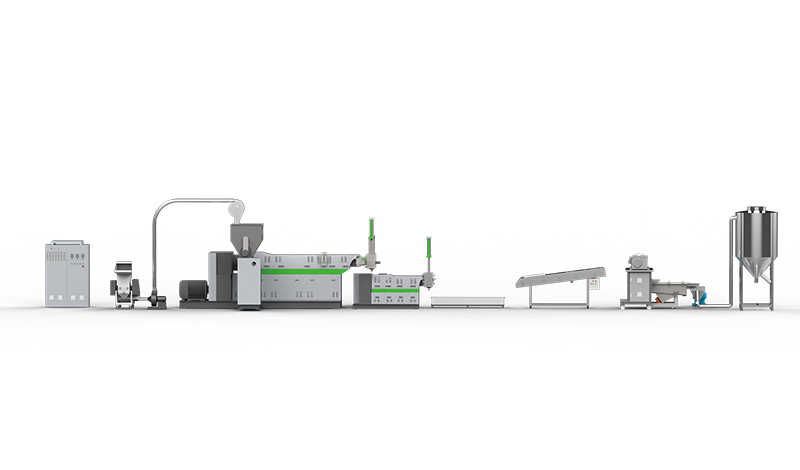

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3