Contact us

Structure and composition: The plastic film crusher is […]

Structure and composition:

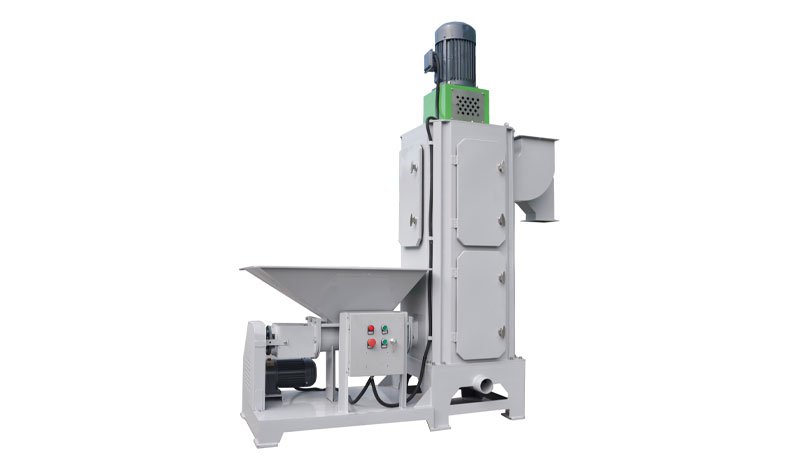

The plastic film crusher is composed of a motor, a hard-tooth surface reducer, a rotating knife shaft, an imported movable knife, a frame, a base, a box, and a working platform.

Product Usage:

Suitable for crushing all kinds of waste films, agricultural films, packaging films, plastic bags, greenhouse films, ton bags, snakeskin bags, space bags, food bags, cement bags, waste fishing nets, etc. (The size and shape of the material can be according to user requirements adjust). The model machine runs at low speed, and the noise and dust can reach high environmental protection standards. The thickness of the tool and the number of claws can be changed according to different materials.

Performance characteristics:

1. Power distribution box: The transmission gear has been forged and high-frequency quenched, which has a long service life.

2. Fixed knife: The fixed knife plays a role of guiding the material and can prevent the material from being broken back and clean the blade.

3. Fixed knife fixing frame: fixed fixed knife function, optimized tool replacement function, making tool maintenance and replacement more efficient.

4. Sealing: The unique sealing structure can completely protect the machine even when handling liquid materials.

5. Bearing seat: The bearing seat adopts a split type, which can quickly remove the cutter shaft, blade, sealing system, bearing, and other components, and is easy to maintain and replace the cutter.

6. Movable knife: D2 is used for heat treatment and tempered as a whole. The hardness and toughness of the tool material are the same inside and outside, and it has high strength and service life. The tool can be used repeatedly, and it is blunt in proportion to the original thickness. Bianling's tools can still be used.

7. Cutter shaft: the use of high-strength materials, after quenching and tempering, high-frequency processing and then milling the hexagonal matching tool, the force is not afraid of damage.

8. The feeding hopper and frame can be designed reasonably according to customer requirements.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3