Contact us

A RECYCLING MACHINELINE is an electronic device used to […]

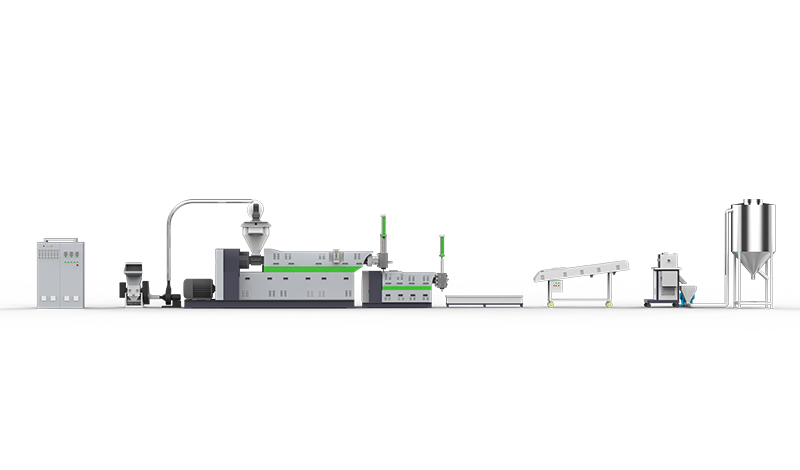

A RECYCLING MACHINELINE is an electronic device used to recycle scrap metal and recover precious metals like nickel, copper, and brass. A small hand crank machine is fitted with a coil spring and a cutting tool that can cut through the metal flakes. After the machine cuts through the flakes it is pushed by hand and gravity pulls the metal into a collection bag. After the metal has been collected in a bag it is electronically processed then recycled. A RECYCLING MACHINE Line is used in a variety of applications including metal recycling for building construction Industry, automotive repair and refinishing, and other uses such as land fill, road side recycling and oil separator applications.

A RECYCLING MACHINE LIST is used to determine the type of material removed from the bottom of the sorting cup. It is used for applications where a high degree of automation is required. The types of RECYCLING MACHINE LISTs are as follows; Plastic Bottle Recycling Line, Oil Collection Lines, Paper Bottle Recycling Lines, Upholstery Bottle Recycling, and Recyclable Can Liners. Each of these categories of recycling machine lines have different processing requirements.

A RECYCLING MACHINE LIST is considered to be a fully automated equipment system that recycles both scrap metal and finished products. It is considered a complete plastic recycling system because it recycles both plastic and non-plastic materials. A machine that is considered to be a fully automated equipment system is one that has all of the required components in place. This includes an area that is heated to accept raw material such as metal flakes. The area is also lined with paper to collect the collected materials. The machine is then hooked up to a roller that transfers the finished product from the sorting cup onto the receiving roll.

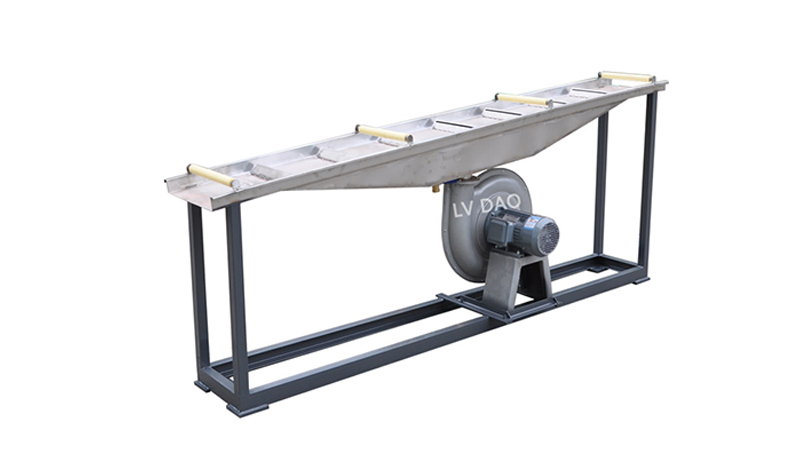

A RECYCLING MACHINE LIST has two primary parts; a water-powered dewatering machine and the reel assembly. The machine that runs the machine also has an impeller. The water used in the dewatering machine is typically recycled by the use of a dewatering rinse. The blades of the machine can also be replaced as needed.

A RECYCLING MACHINE LIST has an optional Washing and Friction Washing action. If a person has a large inventory they may choose to reduce manual sorting and increase the automation of their dewatering machines. With a manual sorting machine the process of manual sorting and washing take longer and use more energy. A fully automated machine has the ability to reduce manual washing and rinsing steps while increasing the efficiency of their dewatering cycle.

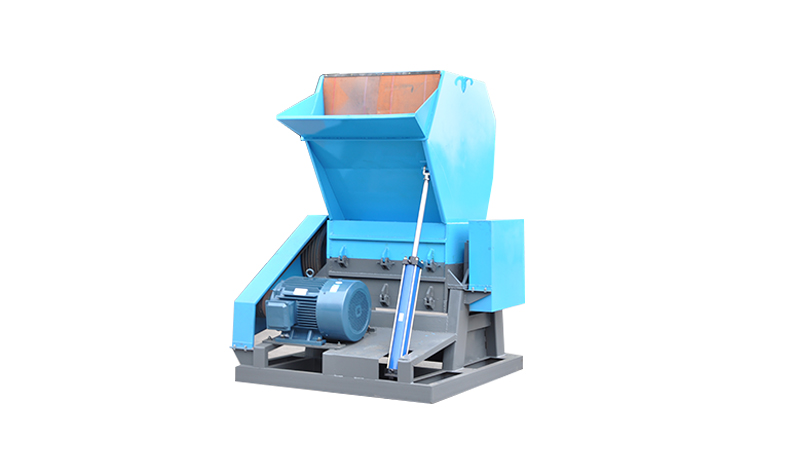

The blade rotator assembly, sometimes called a "crusher" rotator, is where the mechanical parts (lubricated bearings) attach to the machine's crankshaft. The crusher has a screw threaded on one end and a ball on the other. The screw is turned by a power cord so the ball rolls along the metal surface that the crusher is attached to. As the crusher rotates the screw forces the ball against the metal surface of the crusher blades.

The RECYCLING MACHINE LIST is the part of the machine that takes care of paper and plastic bag waste. The paper and plastic bags are broken down into their individual components (such as pieces of plastic tubing) and the little pieces are collected on a RECYCLING MACHINE LIST. The sheet of plastic tubing is pushed into a recycling compartment. There are two ways that the RECYCLING MACHINE LIST can operate: manual processing or automatic processing.

The manual processing starts by collecting one glass bottle from each customer. These bottles are placed into a recycling container before they are placed into a drum. If there are no bottles to be collected then the drum is moved to the recycling line. A RECYCLING MACHINE LIST is used to collect the plastic waste from the drum and place it on the appropriate recycling line.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3