Contact us

There are several benefits of buying a machine for wast […]

There are several benefits of buying a machine for waste plastic recycle. It contributes to the bottom line of a business and reduces the amount of raw materials that are wasted. Additionally, it is more energy efficient and has increased productivity, thus contributing directly to the business's profitability. It also reduces waste in landfills and has a positive impact on the earth, as it reuses plastic products instead of sending them to a landfill.

To make recycling more accessible to everyone, Precious Plastic, a Dutch recycling company, has developed videos that show how to build a recycling machine. Their videos demonstrate how to construct basic machines and use universal parts to create a fully functional recycling workshop. They've even created a map to help DIY recycling enthusiasts find one in their area. There are many ways to build a plastic recycling machine. Here are some examples. You can also learn about building a mini recycling workshop in a shipping container.

The first step is to make a prototype. A machine like this is a step in the right direction, since it follows the industrial plastic recycling process. Once assembled, it will melt down the plastic shreds and create a new product. The next step will be determining what use the machine will have. Eventually, Hakkens hopes to bring the machines to the farmers' market. For now, the machines are slated for the Maker Hub.

Plastic recycling also has several advantages. The process of recycling plastic waste is more efficient and effective than ever before. It will also provide a carbon source for scrap steel recycling. In addition, it will also improve the quality of recycled products. These benefits make the investment worth it. If you're considering purchasing a machine for waste plastic recycle, make sure you read these reviews. You'll be glad you made the decision to invest in one!

Various types of machines for waste plastic recycling are available. Some of the machines can be used to process as little as 40 kg/h. Others can recycle as much as 150 kg of waste plastic per day. For the most part, though, the cost of a machine for waste plastic recycle is dependent on its output capacity and its size. For example, a machine with a high capacity can process as much as 150 kg of waste plastic per hour.

Several methods of plastic recycling exist, and the best one is the one that is most efficient and economical for your business. One of the most common methods is to combine safe waste removal with value-added recovery as a new raw material. However, despite the benefits of this method of waste plastic recycling, it may not always be beneficial. Recycling plastics can also reduce energy and virgin raw materials consumption, lowering air and water pollution. Moreover, it can help you save money when crude oil prices are high.

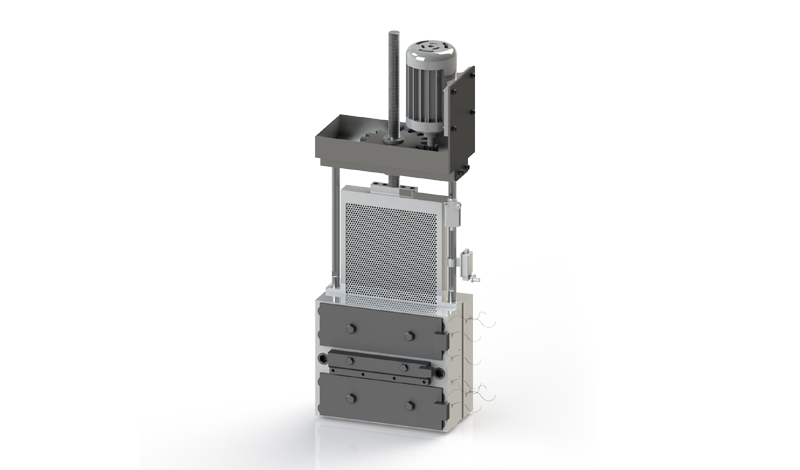

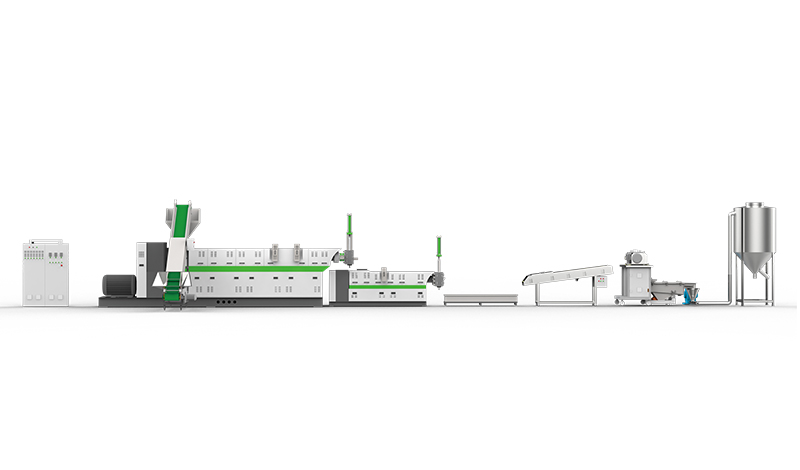

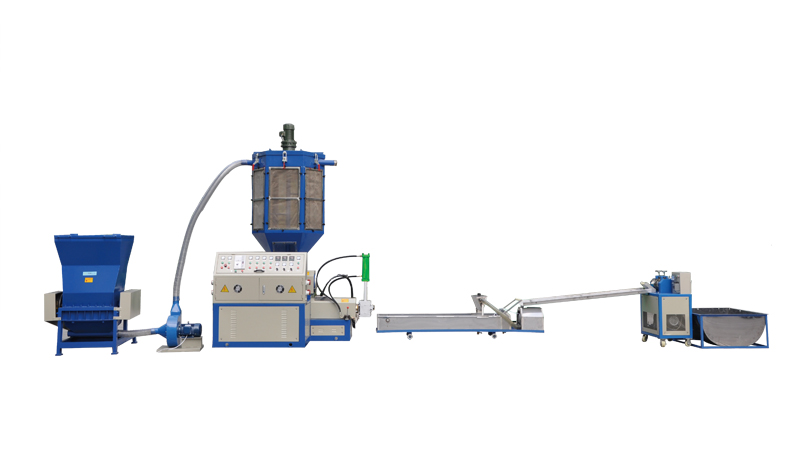

FOAM RECYCLING MACHINE LINE

1.For EPS XPS foam recycling ans pelletizing.

2.Special screw with high speed of compressing and melting.

3.Integration of foam crushing-loading-pelletizing for easy operation.

Product Details

Model Screw dia(mm) Long dia ratio Output(kg/h) Screw rotate speed(r/min) Power(kw)

LDG-SJP-160-95 Φ160、Φ95 4:1、8:1 60-90 560 15/7.5

LDG-SJP-185-105 Φ185、Φ105 4:1、8:1 100-150 560 22/7.5

LDG-SJP-220-120 Φ220、Φ120 4:1、8:1 150-200 560 37/11

LDG-SJP-250-125 Φ250、Φ125 4:1、8:1 200-250

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3