Contact us

If you have ever considered buying a plastic film recyc […]

If you have ever considered buying a plastic film recycling machine, you've probably noticed that they can be expensive. After all, they require a substantial investment and a lot of labor. Still, there are some benefits of owning one. Here are just a few of the reasons to do so. Read on to learn more! And don't forget to research the recycling machine that's right for you. Hopefully, you'll find one that meets your needs!

There are many different types of plastic film recycling machines available, each with its own unique benefits. Depending on your needs, you can get a PP/HDPE reprocess machine to process the material. This kind of machine can accept all types of plastic waste, including raffia. Once processed, these pellets can be used to manufacture high-quality yarns, molded components, and even rope. Another advantage of a PP/HDPE recycling machine is that they can accept polypropylene residues.

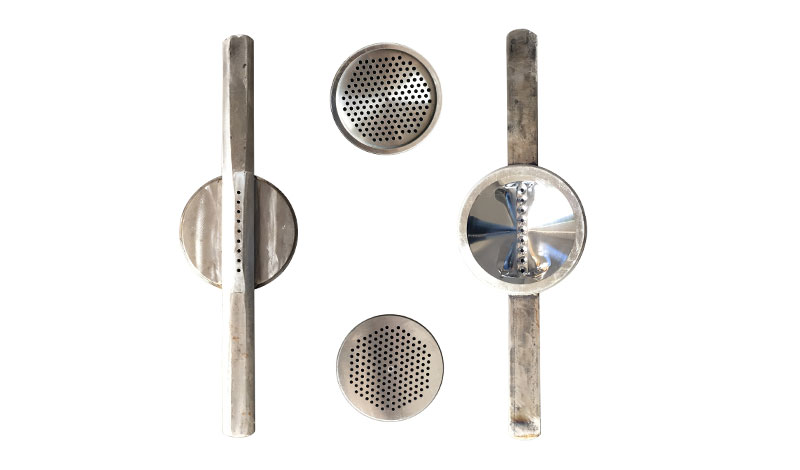

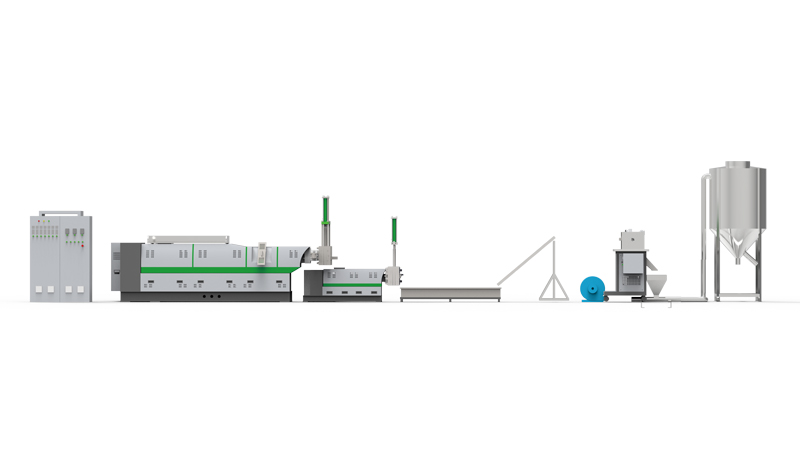

The complete plastic film recycling line consists of various machines to process the different types of plastic films. Each machine has a variety of components, including a plastic crushing and cleaning machine, a rinsing tank, a dewatering system, a pelletizing machine, and a cooling tank. The line is ideal for both small and large plastic recycling plants and can be customized to meet your requirements. For more information on this machine, contact a plastic film recycling machine manufacturer today!

Our products has robust and versatile system that delivers consistently high pellet quality. It includes a patented Preconditioning Unit that preheats plastic before processing, minimizing the amount of energy needed for plastification.

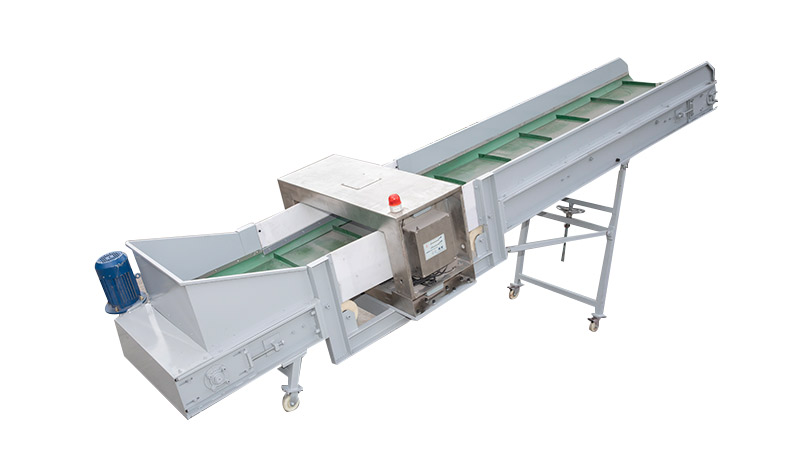

Unlike traditional paper recycling equipment, a plastic film recycling machine can also separate dirty film. The machine's sink float separation system allows it to separate materials that float and those that sink. The majority of plastic films, such as PP and PE films, float. While other contaminants, such as glass and metals, sink to the bottom of the tank. A screw conveyor removes these contaminants and makes clean plastic film. The machine also has an automatic lubrication system for the entire machine's lifetime.

The Society of Plastic Industry provides a system for sorting and processing plastics. This classification system features a number surrounded by a three-arrow recycling symbol. Examples of plastics that can be recycled include low-density polyethylene, #2 plastic, and #4 plastic. Most plastic trash bags are less than one mil thick. It's extremely light-weight. A single plastic t-shirt bag weighs less than one pound, and a 500-square-foot plastic lumber deck can contain approximately 140,000 bags.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3