Contact us

A plastic mixer is an ideal tool for mixing various mat […]

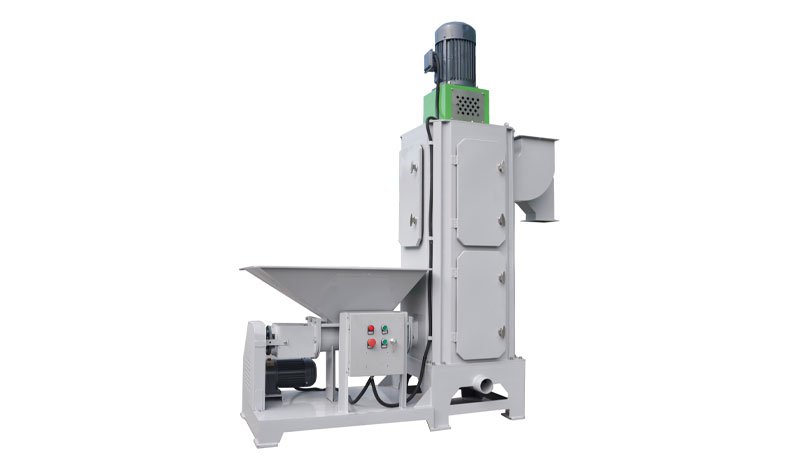

A plastic mixer is an ideal tool for mixing various materials. It can mix different kinds of plastics, white oils, aluminum powders, additives, and waxes. This machine is easy to operate, lightweight, and compact. Its efficiency is high, and it produces low noise. Its many features make it a popular choice for industrial use. Read on to find out how it can benefit your business. Here are a few reasons why you should invest in a plastic mixer.

The first and most important feature of a plastic mixer is its mixing efficiency. In this machine, the melted material is first divided into equal segments, and then it is continuously cross-blended. This process increases the consistency of plastifying, reduces color differences, and reduces the crystallization point. Another benefit is that it is low-priced, and suitable for mixing various chemical materials. Once finished, it is ready to be fed into an extruder or hot press.

The next most important feature of a plastic mixer is its low noise, high efficiency, and versatility. It is best used in plastics manufacturing, and can be used in a wide range of industries. Among these, plastic mixer machines are popular for wood plastic, PVC powder, and plastic particles processing. These machines can also be used in a variety of other processes, including lattice board and SPC floors. It is designed with three layers that rotate the raw material while mixing.

Safety should also be a consideration. Mixers have many potential hazards. Check for fixed guards on agitators, sample points, and bars. These features can result in leaks and spills, thereby putting your employees and products at risk. Consider other operational hazards, such as overfilling and underfilling, which may result in overpressure, splashing, or mechanical damage. Additionally, be aware of agitator shafts and ejected objects.

The dosing pumps are directly connected to the molding machines, and they work together synchronously. They are designed to be modular, and can be customized to accommodate two or more additives. The screws are chrome plated to ensure durability. Some models have high-accuracy hybrid stepping motors. They also come with a microprocessor, making it easy to customize them to suit your needs. If you have a complex formulation, you can also select a high-speed mixer, or combine two or more pumps.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3