Contact us

Plastic waste is one of the major environmental problem […]

Plastic waste is one of the major environmental problems facing the world today. The excessive use of plastic has led to a situation where plastic waste is piling up in landfills and polluting the oceans. However, with the invention of the plastic granule cutter, we are one step closer to reducing plastic waste and saving the environment.

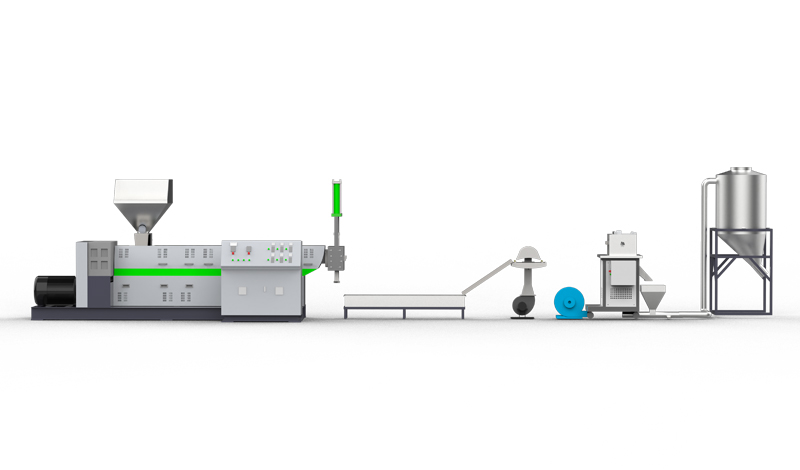

The plastic granule cutter is a machine that cuts plastic waste into small, uniform pieces. These small pieces, known as granules, can then be used as raw material for new plastic products. This innovative machine has the potential to significantly reduce the amount of plastic waste that ends up in landfills and the ocean.

The plastic granule cutter works by using a rotating blade to cut plastic waste into small pieces. The machine is capable of processing different types of plastic, including PET, PP, PE, and PVC. The granules produced by the machine are of a uniform size, which makes them ideal for use as raw material in the production of new plastic products.

One of the biggest advantages of the plastic granule cutter is that it can process large volumes of plastic waste quickly. This means that it is ideal for use in industrial settings where large amounts of plastic waste are produced. By using the plastic granule cutter to process their plastic waste, companies can reduce their environmental impact and improve their sustainability credentials.

Another advantage of the plastic granule cutter is that it can be used to recycle plastic that is otherwise difficult to recycle. For example, some types of plastic, such as PVC, are difficult to recycle using traditional methods. However, the plastic granule cutter is capable of processing PVC waste into granules that can be used as raw material for new plastic products.

The plastic granule cutter is also cost-effective, especially when compared to traditional recycling methods. For example, sending plastic waste to a landfill can be expensive, as companies have to pay for the transportation and disposal of the waste. However, by using the plastic granule cutter to process their plastic waste, companies can turn their waste into a valuable resource that can be used in the production of new products.

In conclusion, the plastic granule cutter is a game-changer in the fight against plastic waste. This innovative machine has the potential to significantly reduce the amount of plastic waste that ends up in landfills and the ocean. By using the plastic granule cutter to process their plastic waste, companies can reduce their environmental impact, improve their sustainability credentials, and save money in the process.

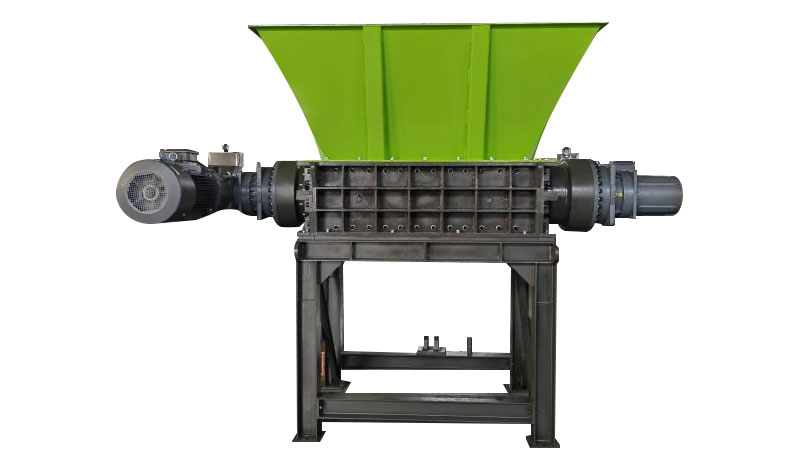

PLASTIC GRANULE CUTTER FPB-100-200

CAPACITY :150-300KG/H

Suitable for granulating after extrude, making it uniform, simple and durable,highly cost effective.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3