Contact us

Using a plastic pelletizing line, you can turn w […]

Using a plastic pelletizing line, you can turn waste plastic into pellets. This is a highly efficient and versatile method of processing plastics. Pellets can be used for a variety of applications, including plastics manufacturing, recycling, animal feed and food processing. Pellets are convenient for packaging and easy to handle.

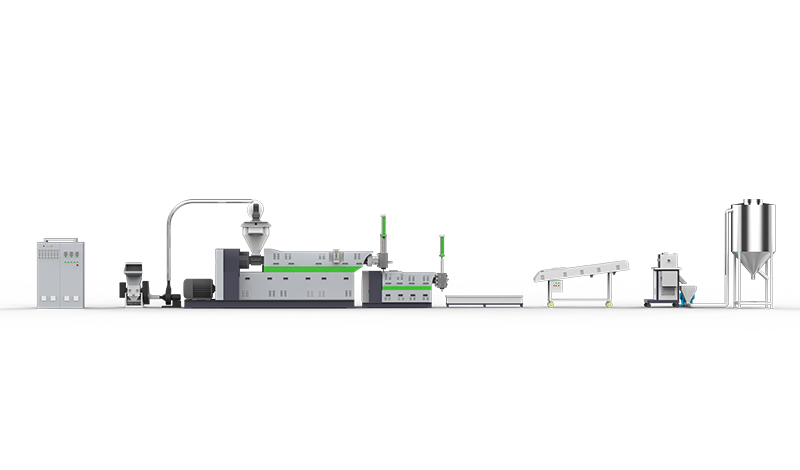

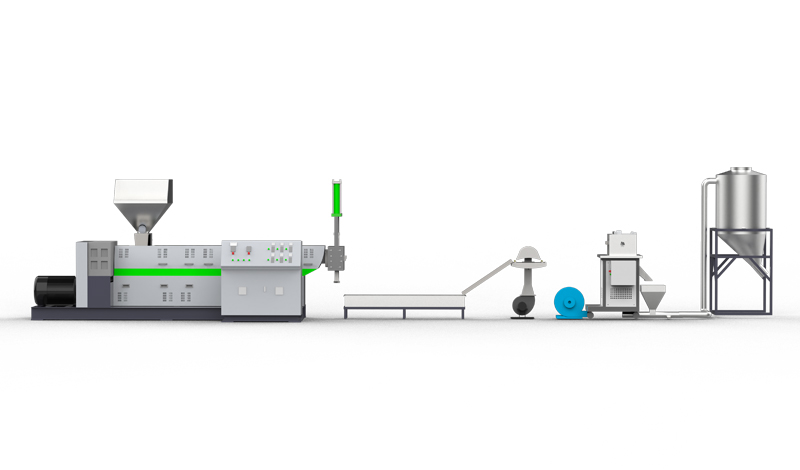

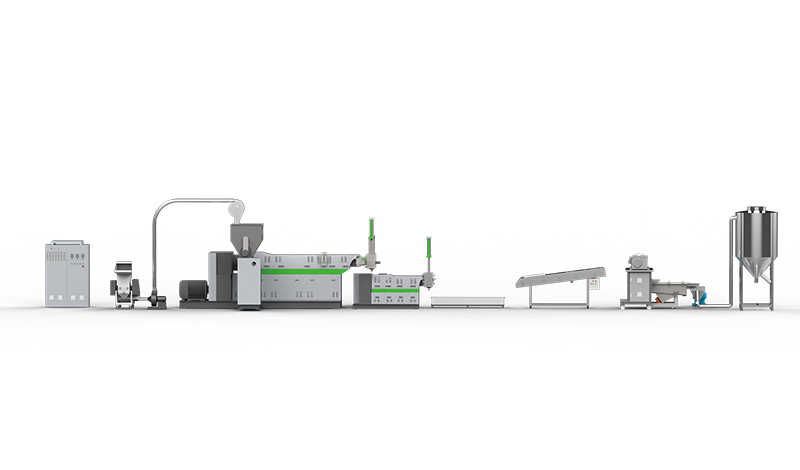

The basic equipment of a plastic pelletizing line includes the pelletizer, the granulator, the high mixer, a vibrating distribution screen and an automatic hopper. These are designed to work together to create a high quality product. The granulator is a special machine that is designed for high efficiency. The pelletizer has an automatic temperature control and low power consumption.

The pelletizing line also uses a high-quality filter system to help ensure that the pellets are of the highest quality. This line is designed to process a variety of waste plastics, including post-industrial plastic, plastic film and waste PET. It also features a dual channel system that helps to prevent leaking. This system is also designed to process larger printed areas.The pelletizing line is also designed with a water-ring pellet cutter that helps to recycle waste plastics. The water-ring pellet cutter can process a wide range of materials, from 100-500 kg/h.

The pelletizer has an automatic screen changer to ensure that the process is safe and efficient. A hydraulic net changer helps to filter out impurities from the plastic. It also features an electric control panel to make the operation smooth. Its ceramic heaters ensure that the plastic is heated evenly and provides a smooth result.

The PP PE film pelletizing line has a water ring pellet cutter that helps to recycle waste plastic films. This system is commonly used in plastic recycling plants. It is also widely used in plastic films manufacturing plants. This pelletizing line can also be used for recycling post-customer plastics.

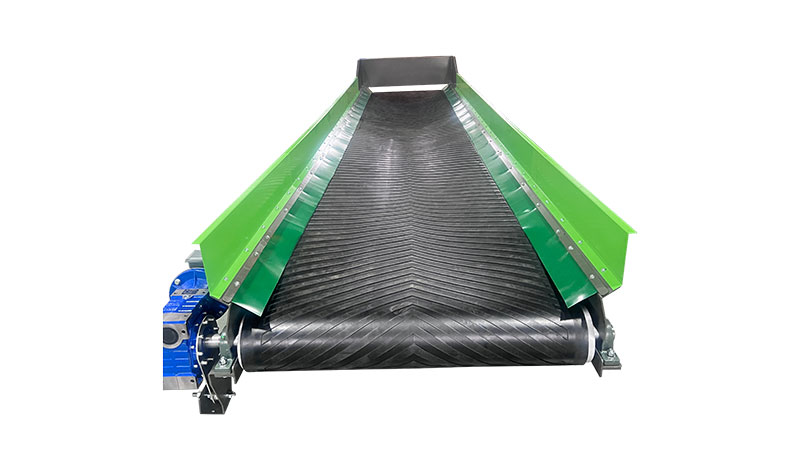

The pelletizing line also has a cutter compactor that helps to maintain a stable feeding of materials. It also features a multi-exhausting and filtering design to ensure that the pellets are of the highest quality. Besides, it has a circular water cooling system that is ideal for EVA and PS. This system also has a split power distribution system, which helps to keep the motor operating safely.

The plastic flake pelletizing line is highly automated and has a long service life. It features a special screw design that helps to ensure the smooth operation of the line. It only requires two workers to operate the line. The line features a filter system to ensure that the final pellet is clean and contains no dust. It also features an air knife to help dry the pellets. It also has a low power consumption and a national energy-saving patented heater. It has an automatic temperature control that helps to ensure that the pellets are of the highest quality.

The plastic pelletizing line has a wide range of uses, including plastics manufacturing, recycling, animal feed, food processing, chemical processing, building materials and environmental protection. Pellets can be purchased at a reduced cost from a variety of companies. They also come in a variety of colors, which is useful for packaging and other applications.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3