Contact us

Film recycling and washing cleaning line product introd […]

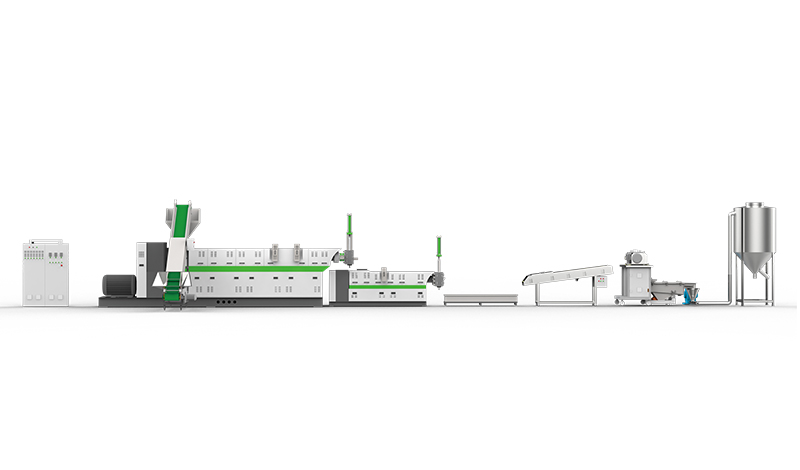

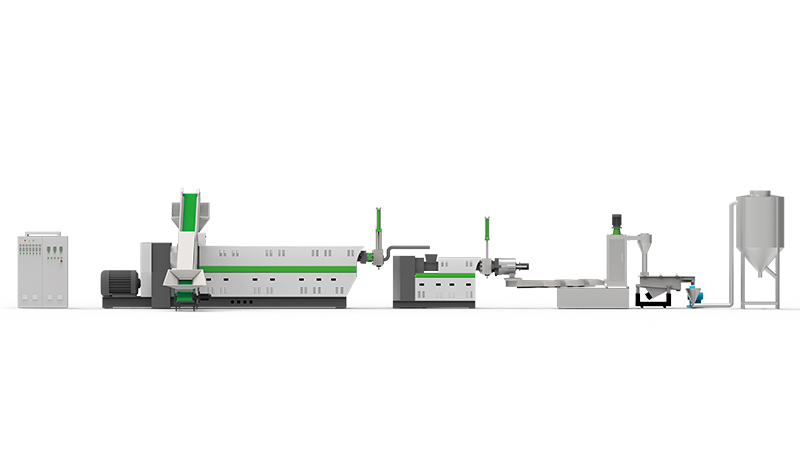

Film recycling and washing cleaning line product introduction: Mainly for the crushing and cleaning of a large number of recycled PP/PE films, agricultural films, mulch packaging films and other soft plastics. The production line is equipped with a conveyor feeding machine, a high-efficiency crusher, and a high-speed friction cleaning machine. Automatic rinsing tank, squeezing dryer, hot air drying system. It has the outstanding advantages of large processing capacity, good cleaning quality, high degree of automation, wide application range, labor saving, safety, environmental protection and energy saving. Combining the equipment during the meal can realize the functions of multiple friction washing, secondary crushing washing, high and low temperature composite washing, and automatic separation and rinsing of submerged and floating materials according to customer needs. Main configuration: belt conveyor, belt feeder, fast and powerful crusher, squeeze dryer, dryer, dryer. Process flow: The production line mainly includes: conveyor, crusher, friction cleaning machine. It is composed of rinsing tank, squeezing dryer, dryer, control cabinet, etc., sorting old plastics, crushing, friction washing, rinsing, squeezing dehydration and other recycling treatments.

The entire production line starts from waste and cleans waste plastic products very efficiently. Waste agricultural film and packaging film are easy to operate, efficient, energy-saving and environmentally friendly.

[PE film recycling and washing line includes the following equipment]

• Feeding conveyor belt – evenly feeding

• Shredder-shredded into bundles or loose woven bags with water, and pre-washed at the same time

• Spiral cleaning machine 1-conveying and cleaning

• Pre-washing machine-to remove foreign matter such as sand and possible small stones

• Spiral cleaning machine 2-conveying and cleaning

• Rinse sedimentation tank 1-clean materials, remove sediment and impurities

• Crusher-crush and clean with water

• Spiral cleaning machine 3-conveying and cleaning

• Horizontal friction cleaning machine 1-cleaning materials, removing sediment and impurities

• Rinse the sedimentation tank 2-further clean the material to remove impurities

• Horizontal friction cleaning machine 2-cleaning materials, removing sediment and impurities

• Centrifugal dewatering machine-material dewatering

• Hot air drying system-further drying

• Bagging system

• Control electric box

Lvdao Film recycling and washing cleaning line Technical features:

• Suitable for all kinds of films and woven bags with a sediment content of up to 80%

• Using circulating water to ensure the cleaning effect while controlling the water flow and evaporation

• The core part of the pretreatment module adopts wear-resistant design to ensure the continuous operation of the system for a long time

• The pre-crushing and pre-washing system efficiently removes most of the sediment and other impurities, protects subsequent equipment, and greatly increases the service life of the fine crushing and cleaning system

• Pertinent design of the fine crushing system, the size of the crushed film is uniform and easy to clean

• The high-speed centrifugal cleaning system applies corresponding blade strikes to different materials at a suitable rotation speed to achieve a good cleaning effect

• The drum of the cleaning tank is designed for high-pressure underwater cleaning, which can remove residual impurities to a large extent; the claw-type uniform speed discharge ensures the discharge

• Evenly control the water content at the same time to provide the process basis for the dehydration module

• The film drying technology combining centrifugal dewatering, screw squeezing and high temperature hot air strictly controls the moisture content of the finished product within 5%, which is suitable for high-quality granulation requirements

• After theoretical calculations and multiple actual measurements, the details of the mechanical operation of the crushing, cleaning, and drying links are adjusted to avoid material loss due to excessive processing

• Automated control of the whole line, interrelated operation of each unit of the system, which maximizes production capacity and has a predictive function for possible abnormal conditions to ensure the safety of the system to a greater extent

• Can be equipped with corresponding granulation system according to production requirements

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3