Contact us

A plastic pelletizing line can be a great solution for […]

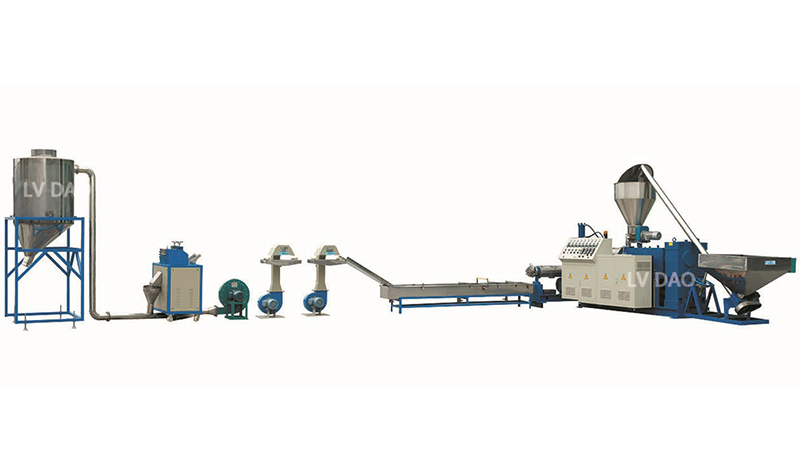

A plastic pelletizing line can be a great solution for recycling plastic bottles, woven bags, and other products. This machine uses a special electromagnetic heating technique to convert waste plastic into granules. Then, the pellets are conveyed into a silo where the drying process completes. A centralized control cabinet controls the entire process. The pellets are then ready to be reused. The process is fast, efficient, and cost-effective.

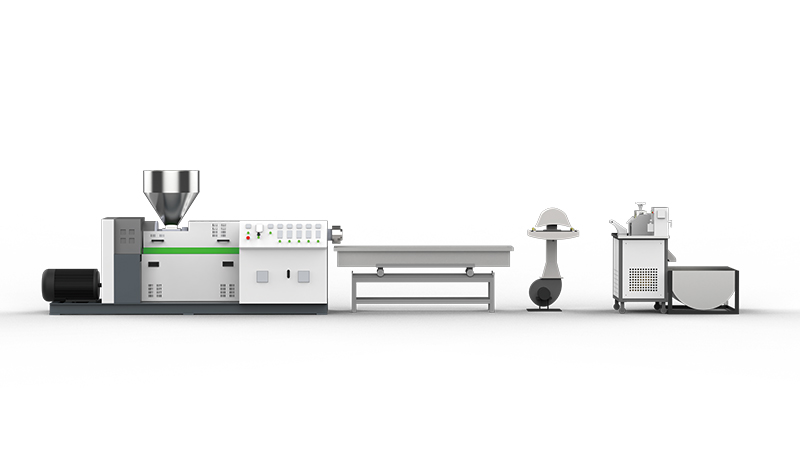

Plastic pellets are recycled materials, and the pelletizing process is an excellent choice for both small and large-scale businesses. In addition to the plastic recycling process, it also creates a dust-free product that is easy to store and clean. A plastic pelletizing line uses a tandem granulation system to manufacture the granule material. The machine is connected to an extruder, which performs the extrusion work.

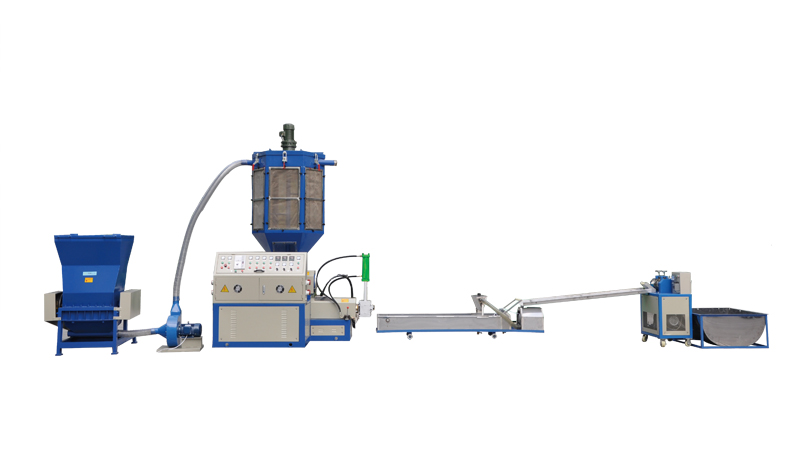

A plastic pelletizing line uses a combination of extrusion and crushing equipment. This machine is equipped with a cutting compactor and granular cutter. The final product can then be used for wiredrawing or injection molding. A granulating line can also be combined with a granulating line to make more products and save money. A plastic pelletizing line is a smart investment. A small-scale company can start a plastic pelletizing business with one machine and use several machines to produce a variety of products.

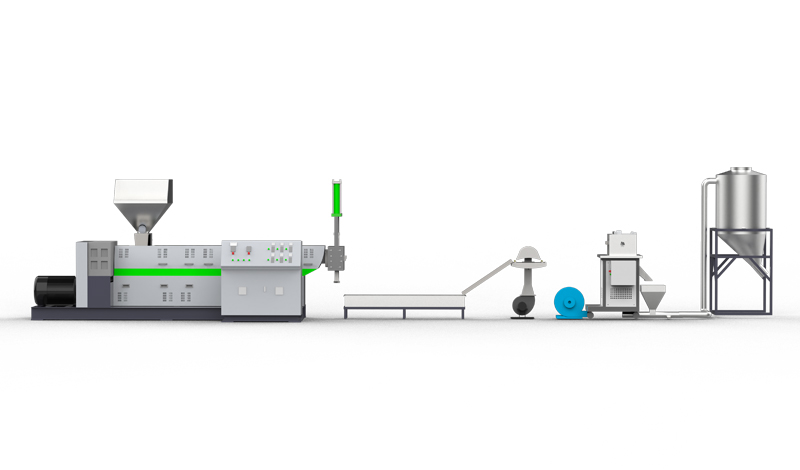

A plastic pelletizing line can process both waste PP PE film and other recyclable materials. The granules are cut in water and then separated by size. A water-ring die face hot-cutting machine is the main part of this system. A single screw extruder then performs the extrusion work. It can be easily operated, and produces a quality product. Moreover, plastic pellets are easy to store and clean.

A plastic pelletizing line is a valuable tool for recycling waste materials. It can reduce energy and environmental pollution, and it can also help your business by protecting the environment and reducing your carbon footprint. A single plastic pelletizing line can be used in multiple applications. In a small-scale plant, it is ideal for the production of a variety of different types of polymer. However, it can be used in a wide range of industries.

A plastic pelletizing line can be used to make a variety of products. A plastic pelletizing machine is a great way to recycle plastic scraps. You can sell your recycled materials and toll pellets. It can be used in many industries, from packaging to automobiles and household appliances. You can also sell granules to a variety of companies. The plastic pelletizing process is the best way to get a high-quality product.

A plastic pelletizing line is an excellent option for recycling washed plastic materials. Its unique features allow it to recycle PVC sheet and pipe flakes in a wide range of applications. A plastic pelletizing machine can also be used to recycle waste plastic in the recycling of other materials, including paper and cardboard. A pelletizing line is an efficient and environmentally-friendly way to recycle waste and reuse it. It can also be used to make food and beverages.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3