Contact us

Enhancing recycling efficiency is a central function of […]

Enhancing recycling efficiency is a central function of Plastic Crushers, making them indispensable in the effort to reduce plastic waste and promote a more sustainable future.

Improved Material Consistency:

Plastic waste often arrives at recycling facilities in diverse forms and conditions. Some plastics may be dirty, contaminated, or in various stages of degradation. Plastic Crushers play a crucial role in transforming this heterogeneous input into a more consistent and manageable material. By breaking down plastic items into smaller, uniform fragments, crushers create a more standardized feedstock for recycling processes. This consistency is essential for producing high-quality recycled materials.

Streamlined Sorting and Classification:

The smaller, consistent plastic fragments generated by crushers are easier to sort and classify. Automated sorting systems within recycling facilities can operate with greater precision and speed when handling materials of uniform size and shape. This improves the accuracy of sorting operations, ensuring that plastics are properly categorized based on their resin types and qualities, which is fundamental for effective recycling.

Enhanced Cleaning and Decontamination:

Many plastic items are contaminated with dirt, residues, or other impurities, which can hinder the recycling process. Crushers break down plastics into smaller pieces, making it easier to clean and decontaminate them. This preparatory step allows for more effective removal of impurities and contaminants, resulting in a cleaner and higher-quality material ready for recycling.

Efficient Melt and Reprocessing:

Recycling plastics often involves melting and reshaping the material into new products. Smaller plastic fragments, as produced by crushers, require less energy to melt and can be processed more efficiently. This reduces the energy consumption during the melting and reprocessing stages, contributing to cost savings and lower environmental impact.

Reduced Wear and Tear on Equipment:

In recycling facilities, crushers act as a crucial buffer that reduces the strain on downstream equipment. The smaller, uniform plastic fragments are less abrasive and place less stress on machinery such as extruders and molding equipment. This, in turn, prolongs the lifespan of recycling machinery, leading to cost savings and more sustainable operations.

Energy Efficiency:

The process of reducing the size of plastic waste using crushers consumes energy. However, this energy expenditure is offset by energy savings achieved in subsequent recycling steps. Smaller, uniform plastic fragments require less energy to clean, sort, and reprocess, leading to a net gain in energy efficiency throughout the recycling process.

High-Quality Recycled Materials:

The enhanced recycling efficiency made possible by Plastic Crushers results in the production of high-quality recycled materials. These materials can be used to manufacture a wide range of plastic products, from packaging materials to construction components. The consistency and cleanliness of the recycled material are essential for ensuring that the final products meet industry standards and consumer expectations.

Economic Advantages:

The efficiency improvements brought about by Plastic Crushers translate into economic benefits for recycling facilities. They can achieve cost savings through reduced energy consumption, less wear and tear on equipment, and enhanced sorting accuracy. Additionally, high-quality recycled materials command better market prices, further contributing to the economic viability of recycling operations.

Reduced Environmental Impact:

Efficient recycling processes, made possible by crushers, have a lower environmental impact. The energy savings, reduced transportation costs, and the production of high-quality recycled materials all contribute to a more sustainable and eco-friendly approach to plastic recycling. This aligns with global efforts to reduce resource consumption and minimize environmental harm.

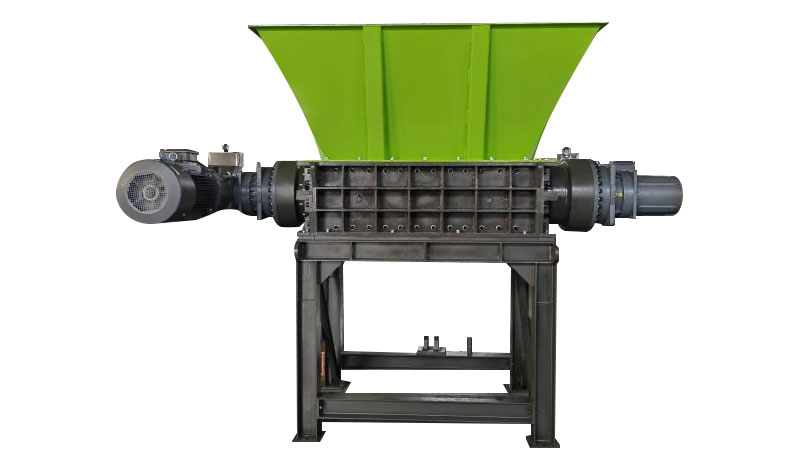

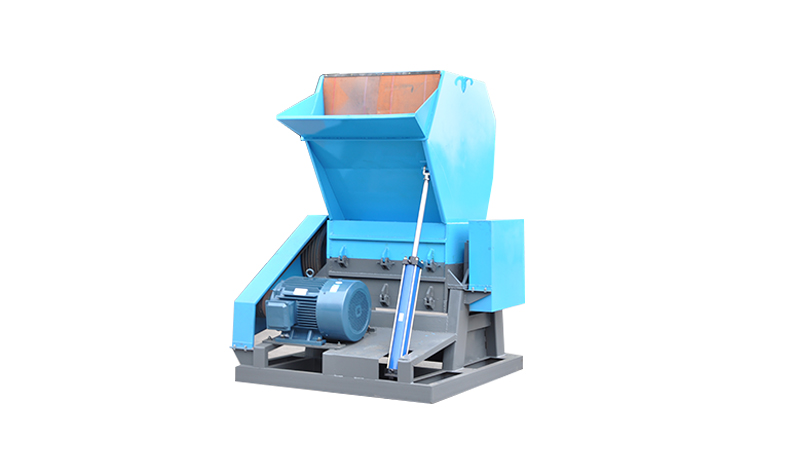

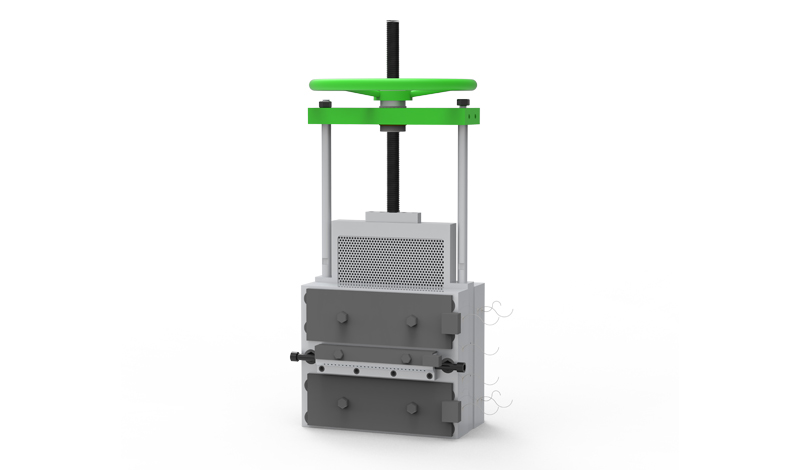

1.Plastic film crusher machine is special used to recycle the waste plastic material.In general, is connected to use cleaning washing line.

2.Plastic film cleaning and crushing machine can crush many kinds of film materials such as woven bags, agricultural film, hand bag,LDPE,HDPE, etc. Which can also remove and clean the dust and impurity the material so that to get the clean plastic materials.With the plastic film cleaning line, you can get clean raw materials very well. And then by the plastic granulator,you can get clean and beautiful granule

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3