Contact us

The feeding machine of the plastic granule cutter is th […]

The feeding machine of the plastic granule cutter is the place to begin of the complete reducing technique. It is accountable for feeding uncooked materials to the reducing device. The design and overall performance of the feed gadget play a key position inside the running performance and reduce pleasant of the slicing system.

Feeding structures can introduce plastic uncooked materials into the reducing gadget in a variety of ways. Here are some common feeding methods:

Manual feeding: This is the simplest technique, the operator manually feeds the plastic uncooked fabric into the feed port of the cutting machine. Although this approach is easy to perform, it isn't suitable for mass production because it limits the production speed.

Automatic feeding device: This system uses computerized gadgets to transport raw substances from a storage container or silo to the feed port of the slicing system. Automatic feeding structures can encompass screw conveyors, belt conveyors, vibrating feeders, etc., which improve manufacturing performance.

Manual or automatic feeder: A feeder is a chunk of gadget in particular designed to feed uncooked cloth to a slicing gadget. While manual feeders require operator intervention, automatic feeders offer ordinary feeds of elements, growing production velocity and consistency.

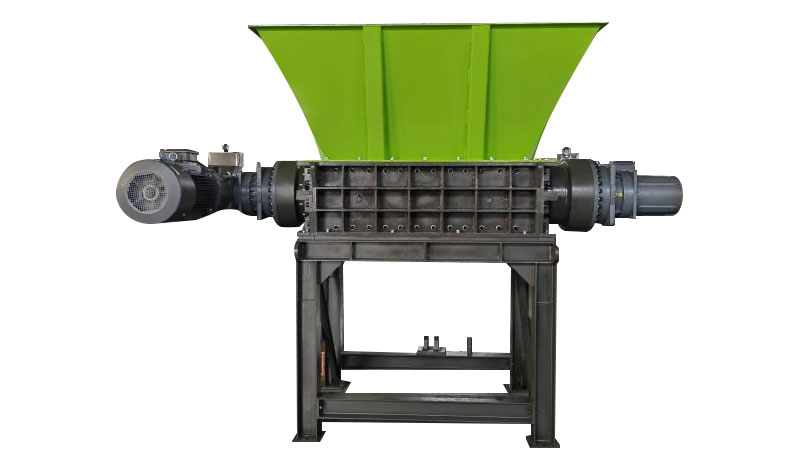

Feeding device components

The feeding device generally consists of the subsequent components:

Feed port: The feed port is the access point for raw substances into the slicing device. It is typically positioned at the top or side of the reducing machine and is attached to different elements of the feeding system.

Raw cloth garage or deliver device: The uncooked fabric garage or deliver device is used to store uncooked substances to feed the cutting device. This may be a field, silo or hopper, the ability of which varies depending on production needs.

Conveying system: Conveying device is used to transport raw materials from the garage or deliver tool to the feed establishing of the cutting device. Different sorts of conveying gadget are to be had, which include screw conveyors, belt conveyors and vibrating feeders.

Feed Control: Feed manage structures are used to adjust and monitor the feed price and quantity of uncooked materials. This may be performed by adjusting the velocity of the conveying equipment, the vibration frequency or the rotational speed of the screw conveyor.

Advantages and Considerations of Feeding Systems

Efficiency: An powerful feeding device ensures that the slicing gadget gets the perfect amount of raw cloth to keep non-stop manufacturing. This helps improve productivity.

Consistency: The computerized nature of the feed machine guarantees a consistent feed of cloth, ensuing in consistent reduce high-quality.

Reduced operator intervention: Automatic feeding systems reduce operator intervention, lowering labor charges and the risk of running mistakes.

However, there are a few things to observe while the usage of and maintaining the feed gadget:

Raw fabric choice: The feed gadget have to be like minded with the plastic raw fabric used. Different raw materials may additionally require one of a kind varieties of conveying system and control structures.

Maintenance and Cleaning: Regular upkeep and cleansing are key to preserving your feed device operating successfully. Impurities and dust in uncooked substances might also affect device overall performance.

Safety: When running the feed gadget, protection techniques must be accompanied to make sure that the operator isn't always injured. Maintaining system and ensuring its safe overall performance is critical.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3