Contact us

The feeder is also called the plastic feeder. The stand […]

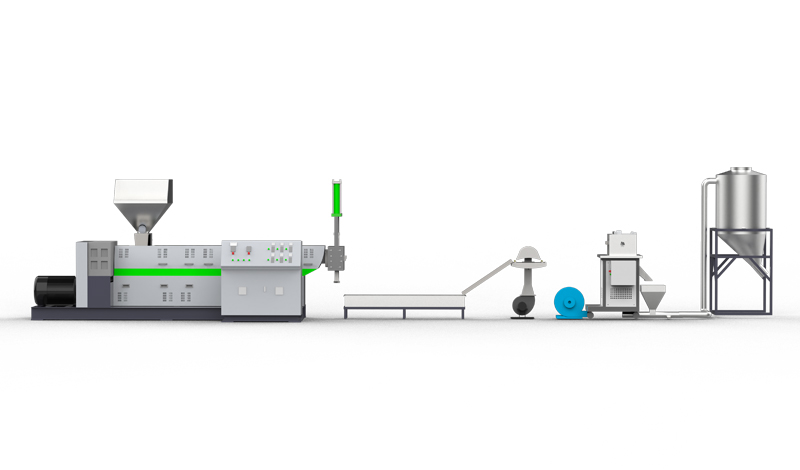

The feeder is also called the plastic feeder. The standard material is a must-have product in the production line of waste plastics. The feeding machine is also divided into a single-type automatic vacuum feeding machine and a split-type high-power automatic vacuum feeding machine.

The vacuum feeder is one of the necessary equipment for the light and heavy industries such as modern industry, pharmacy, food, metallurgy, building materials, agricultural and sideline industries. It provides work efficiency, accurate transportation, reliable quality and durability, and is in the feeding process. The medium raw materials are completely free from moisture, pollution, foreign matter, and no loss. It realizes the self-transportation of the feeding process, avoids the danger of high-altitude feeding, reduces labor intensity, and improves production efficiency. It is one of the necessary for modern enterprise civilized production.

(1) Different positioning methods have different influencing factors. For example, when the mechanical stop is positioned, the positioning accuracy is related to the stiffness of the stop and the speed when the stop is touched.

(2) The positioning speed has a great influence on the positioning accuracy. This is because when the positioning speed is different, the energy of the moving parts that must be dissipated is different. Generally, in order to reduce the positioning error, the positioning speed should be controlled reasonably, such as improving the buffering performance and buffering efficiency of the buffering device, and controlling the drive system to decelerate the moving parts in a timely manner.

(3) Precision The manufacturing precision and installation speed regulation precision of the precision manipulator have a direct influence on the positioning precision.

(4) Weight of moving parts The weight of moving parts includes the weight of the manipulator itself and the weight of the object being grasped. Changes in the weight of moving parts have a greater impact on positioning accuracy. Generally, when the weight of the moving parts increases, the positioning accuracy decreases. Therefore, not only the weight of the moving parts itself must be reduced during the design, but also the influence of the change in the grasping weight during work must be considered.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3