Contact us

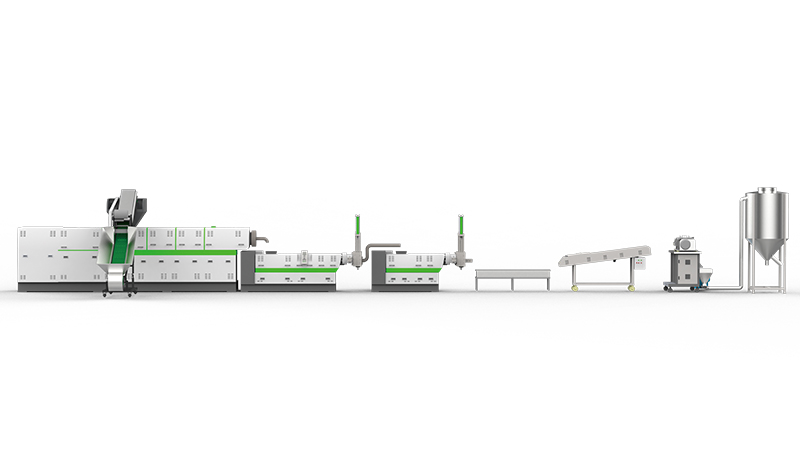

1. Working principle After the material passes throug […]

1. Working principle

After the material passes through the feeding port, under the action of the rotating screw, it is rolled into a dough and rolls along the screw groove. Due to the shearing, compression and agitation of the screw, the material is further mixed and plasticized, and the temperature and pressure gradually increase. High, showing a state of viscous flow, passing through the machine head with a certain pressure and temperature, and finally obtaining a product of the desired shape.

2, use

twin-screw granulator is mainly used for filling, blending, modifying, adding, chlorinating, polypropylene and super absorbent resin processing of rubber and engineering resins.

It can also be used for the extrusion of degradable masterbatch, polyamide polycondensation, polyurethane polyaddition reaction, granulation of carbon powder and magnetic powder, insulation materials for cables, sheath materials, low-smoke halogen-free flame-retardant PVC cable materials and various The preparation of a kind of silane crosslinking material, etc., the small model is mainly used for scientific research and teaching.

The barrel and screw of the parallel twin-screw granulator are designed according to the principle of building blocks, which can be combined in different ways as required. It adopts electric heating and water cooling to automatically control the temperature of the barrel, and is equipped with forced feeding, vacuum exhaust and non-stop screen changing devices.

The twin screw adopts frequency conversion speed regulation, AC motor drive or DC speed regulation, DC motor drive. The deceleration and twin screw drive are in the same box, with compact dimensions. The safety coupling equipped with shear pins can protect the screw and transmission box from damage due to overload.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3