Contact us

The twin-screw extruder is an important machine equipme […]

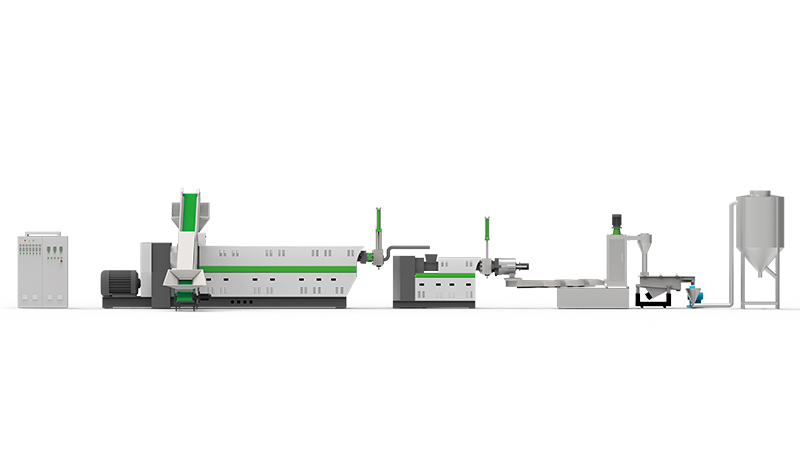

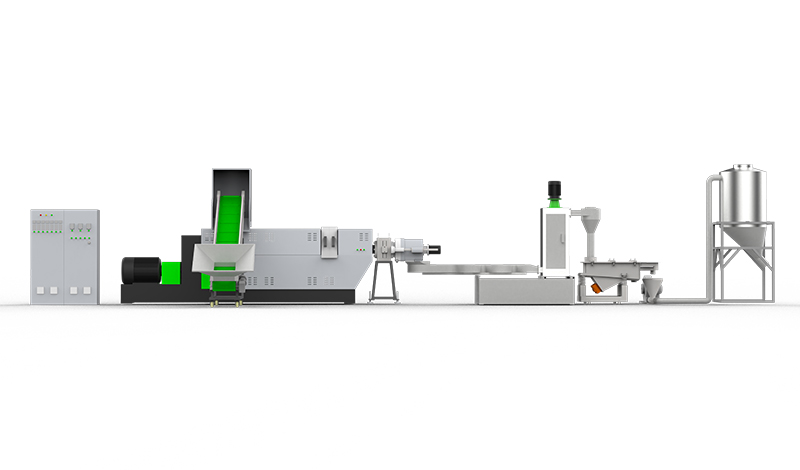

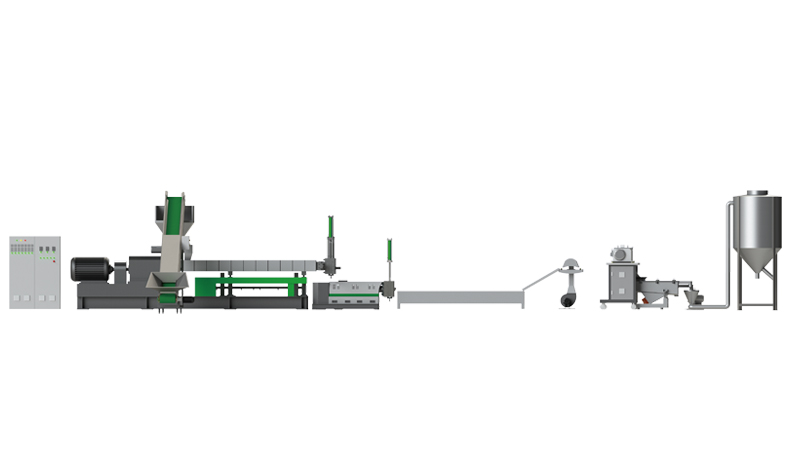

The twin-screw extruder is an important machine equipment in the industrial processing field. Because of its universal adaptability to different materials, it can be applied to the processing of a variety of materials. Friends who are not familiar with industrial processing may be unfamiliar with it. Therefore, the editor decided to give you a detailed introduction to the major advantages of the twin-screw extruder and its operating procedures. I hope that the following explanations can help everyone better understand this advanced industrial equipment.

The main advantages of twin screw extruder

1, good self-cleaning

There is a speed difference in the meshing between the twin screws. Under mutual friction, the occurrence of material stagnation can be reduced, and the self-cleaning property of the co-rotating twin screws is stronger.

2, easy to observe

The twin-screw extruder is easy to open, so it is possible to observe the degree of wear of the threaded elements, the inner liner of the barrel and other parts at any time, so that it can be replaced in time and effectively to avoid product waste caused by component damage.

3, reduce production costs

The openable processing area makes the twin-screw extruder have greater advantages in product color change and material change. And can analyze the mixing process by observing the melt profile on the entire screw. Ordinary twin-screw extruders need to use a large amount of cleaning material for color change, but in some split twin-screw extruders, the barrel can be quickly opened for manual cleaning, which reduces the use of cleaning materials.

4. Improve labor efficiency

When performing mechanical maintenance, the heating and cooling system of the ordinary twin-screw extruder usually needs to be removed first. In the twitch screw and split twin-screw extruder, it is only lifted by removing the necessary bolts and turning the turbine box handle device. The upper half of the barrel can be opened to repair. It not only saves time and reduces the labor intensity of maintenance workers, but also reduces production interruptions caused by equipment wear.

5, high speed

By observing the development trend of twin-screw extruders, we can see that this field is currently developing in the direction of high torque, high speed, and low energy consumption. For example, the increase in productivity brought about by high speed is especially reflected in the split twin-screw extruder, making it more suitable for the production and processing of high-viscosity, heat-sensitive materials.

6, high yield and high quality

Compared with single-screw extruders, twin-screw extruders, especially intermeshing twin-screw extruders, perform better in the solid and melt conveying of materials, and because of the joint operation of the twin-screws, the mixing of materials is more complete. Therefore, it has the advantages of high output, high quality and high efficiency.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3