Contact us

The low-cost plastic shredder is one such machine. It c […]

The low-cost plastic shredder is one such machine. It can rip and shred plastic, extrude the material for 3D printing, and mold it into molds. Videos of how to make this type of machine are widely available online, and show how to build it with simple materials and Universal Parts. These videos can be used to build a complete recycling workshop inside a shipping container.

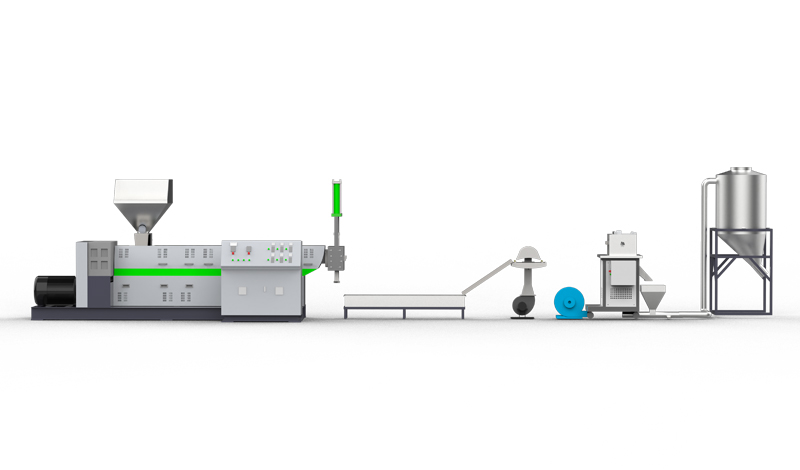

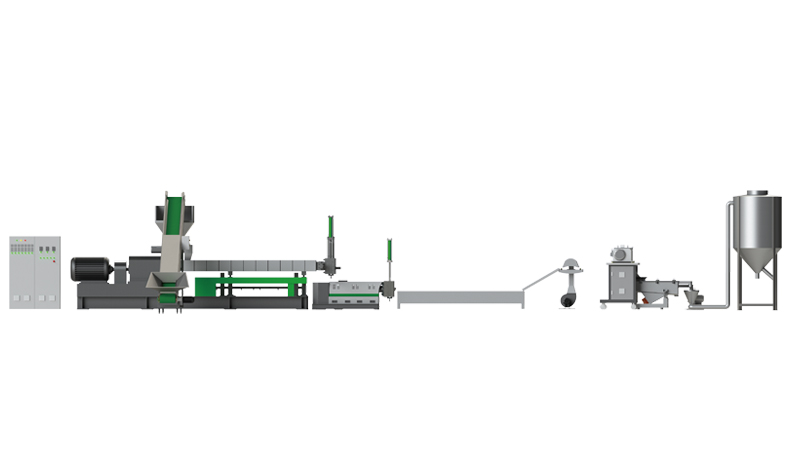

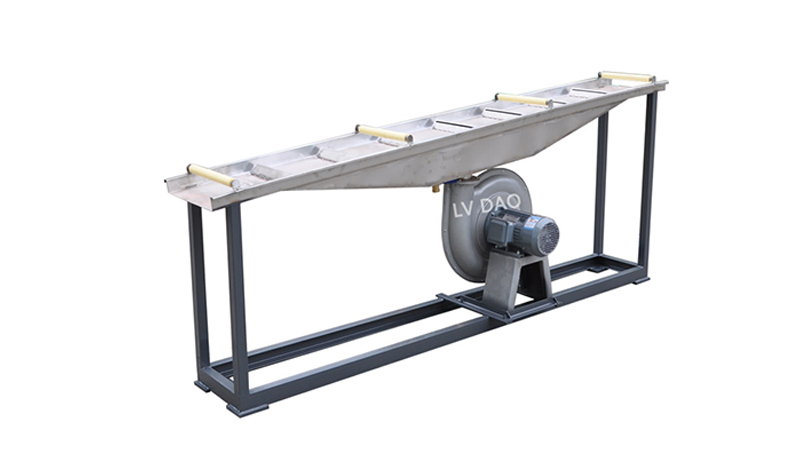

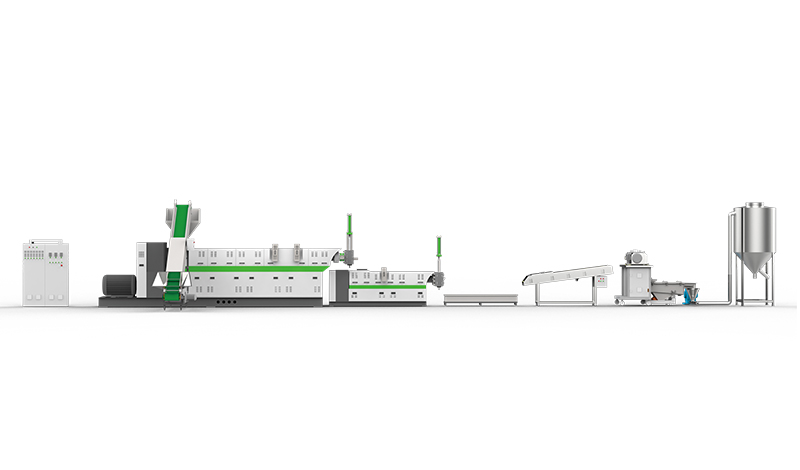

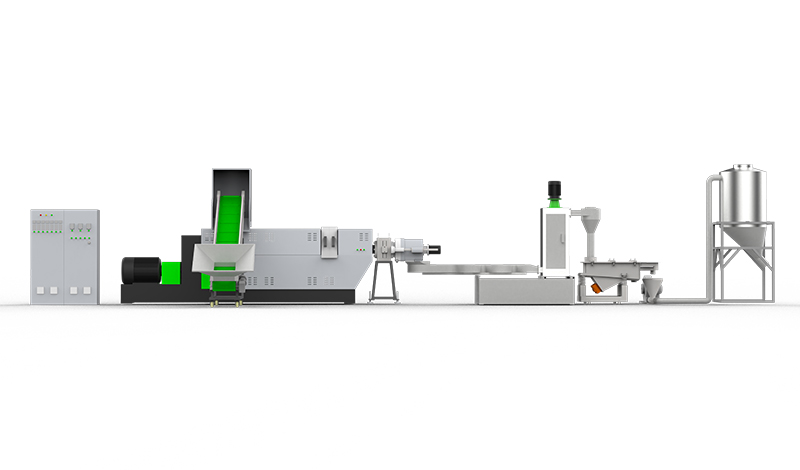

The main function of a plastic recycling machine is to process the waste plastic films and bags. The machines are suitable for most types of waste plastic processing. The machines are fully automated, which makes them popular among plastic processing plant owners. They fully automate the processes of raw material processing, cleaning, feeding, and granulation. They save energy and power and ensure maximum efficiency. They can also recycle glass, metal, and other materials without the use of additional chemicals.

The most popular type of plastic recycling machine is an industrial-sized machine, which can handle many different kinds of plastic. This type of machine is easy to use and is suitable for multiple raw materials. The machine features two positions hydraulic screen changers to keep it working uninterrupted even when changing the filter screen. It is designed according to the type of plastic being recycled. It is easy to use and can be customized according to the type of plastic. The optimum design allows for smashing, mixing, and separating.

A 3 in 1 plastic recycling machine is the most efficient machine in the market. This machine combines the process of slicing, extruding, and pelletizing into one machine. This saves both labor costs and raw material waste. A dual piston hydraulic screen changer keeps the machine operating non-stop when the filter screen needs to be replaced. This ensures that there is minimal waste and a greater production rate. And the best part is that these machines reduce the costs of plastic manufacturing.

A three in 1 plastic recycling machine can do the tasks of shredding, extruding, and pelletizing. Its dual piston hydraulic screen changers keep the machine running nonstop even when replacing the filter screen. This prevents the creation of waste while simultaneously maximizing production. A 3 in 1 plastic recycling machine has multiple benefits. These machines are highly affordable, and offer the highest level of quality and productivity in the industry. If you want to make the most of their investment, buy this type of machine.

This machine can be customized to suit the specific needs of your business. You can select the machine that suits your requirements. These machines are designed to process a wide range of plastic materials. They are able to be used as feedstock for many types of companies. The best ones can be customized to meet your business requirements. You can also order them online or visit a local manufacturing company. You'll be amazed at how much plastic you can recycle and how easy it is!

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3