Contact us

The cleaning and shredding phase of plastic recycling i […]

The cleaning and shredding phase of plastic recycling is a critical step that prepares collected plastic waste for further processing. During this phase, plastic materials are cleaned to remove contaminants and then shredded into smaller, manageable pieces. These processes are essential for ensuring the quality of recycled plastic and enhancing its suitability for subsequent recycling and manufacturing.

Cleaning Processes

Mechanical Cleaning: This process involves the physical removal of contaminants from plastic materials. Various equipment, such as brushes, scrubbers, and high-pressure water jets, is used to remove dirt, labels, adhesives, and other impurities from the surface of plastics. Mechanical cleaning is particularly effective for rigid plastics like bottles and containers.

Chemical Cleaning: Chemical cleaning utilizes solvents or detergents to dissolve or loosen contaminants on plastic surfaces. The choice of cleaning agent depends on the type of plastic and the nature of the contaminants. This method is commonly employed for cleaning plastic films and sheets.

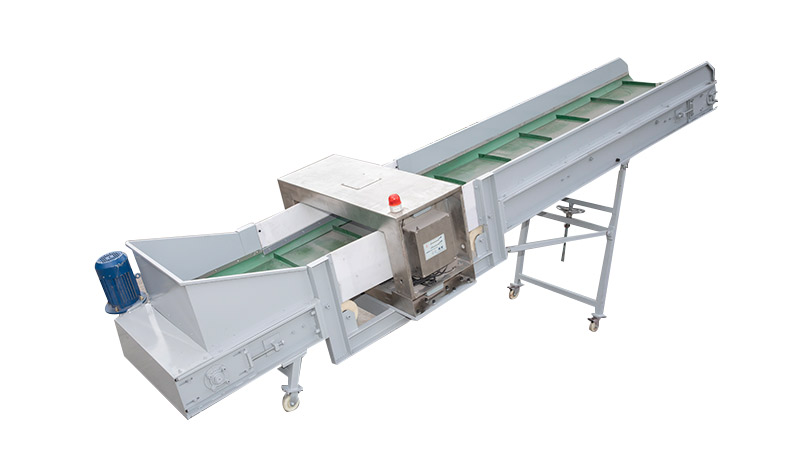

Washing Tanks: Recycling machines often include washing tanks or baths where plastic materials are immersed in water or cleaning solutions. Agitation and turbulence within the tanks help dislodge and remove contaminants. Water recycling systems in these tanks can minimize water usage and environmental impact.

Float-Sink Tanks: Float-sink tanks are used to separate plastics from other materials based on their buoyancy. Plastics are lighter than many contaminants and can float, allowing them to be separated from denser materials. This method is particularly useful for separating plastics from heavier materials like metals and glass.

Challenges in Cleaning

Contaminant Variability: The type and extent of contaminants in plastic waste can vary widely, making it challenging to design a one-size-fits-all cleaning process. Recycling facilities must adapt their cleaning methods to the specific materials they receive.

Energy and Water Consumption: Cleaning processes can be energy and water-intensive, which can impact the overall sustainability of plastic recycling. Innovations in water recycling and energy-efficient cleaning equipment are essential to mitigate these challenges.

Material Compatibility: Different plastics have varying levels of resistance to cleaning agents and mechanical processes. Compatibility testing is crucial to prevent damage to the plastics during cleaning.

Shredding Processes

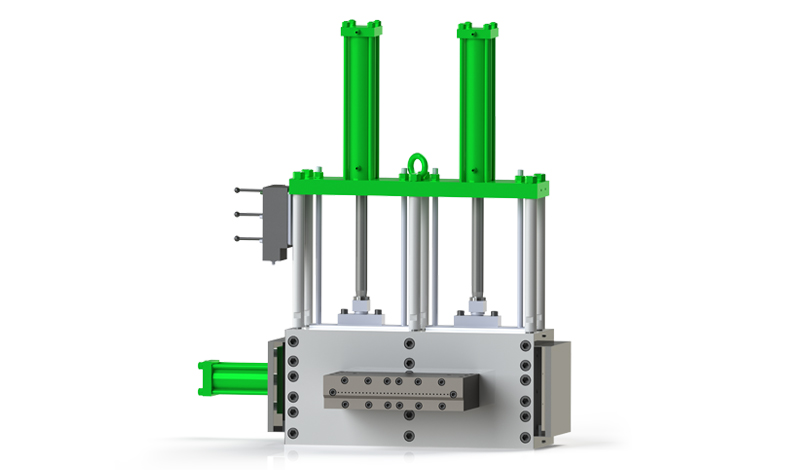

Single-Shaft Shredders: Single-shaft shredders are machines equipped with a single rotating shaft with blades or knives. They are ideal for reducing plastic materials into smaller pieces. The shredding action is typically slow and powerful, making it suitable for thick and rigid plastics.

Double-Shaft Shredders: Double-shaft shredders feature two counter-rotating shafts with blades that work together to shred plastic waste. They are capable of processing a wide range of plastic materials, including thin films and bulky items.

Granulators: Granulators are specialized shredders designed to produce uniformly sized plastic granules or flakes. These granules are easier to handle and transport than irregularly shaped pieces. Granulated plastic is commonly used in various manufacturing processes.

Hammer Mills: Hammer mills use high-speed rotating hammers to break down plastic materials into smaller particles. They are suitable for a variety of plastics and are often used in recycling post-consumer plastic products like electronic waste.

Advancements in Shredding

Size Reduction Precision: Advancements in shredding technologies have improved the precision and consistency of size reduction. Modern shredders can produce uniform particle sizes, which is essential for manufacturing processes.

Energy Efficiency: Shredding machines are becoming more energy-efficient through the use of variable-speed drives, optimized blade designs, and improved motor technologies. These innovations reduce energy consumption and operational costs.

Safety Features: Safety features, such as automatic shut-off systems and user-friendly controls, are integrated into shredders to protect operators and ensure safe operation.

Material-Specific Shredding: Some shredders are designed specifically for certain types of plastics. For example, PET bottle shredders are optimized to process PET plastics efficiently.

Integration with Sorting: Shredding machines are often integrated into recycling lines alongside sorting equipment. This ensures a seamless transition from the sorting phase to shredding and subsequent processing.

This is our company LDG series plastic pelletizing machine.This machine is suitable for recycling EPS XPS foam materials,especially for sorting materials and transform rubbish into treasure. It is an ideal choice for environmental protecting of the supermarket and residential areas. This machine line adopt the fast compact,fast melting, extruding with filter and one-step processing makes the plastic granules.Hot-melted foam and cold-pressed foam are not suitable for this machine because this machine is for loose material.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3