Contact us

The power transmission system of the plastic conveyor i […]

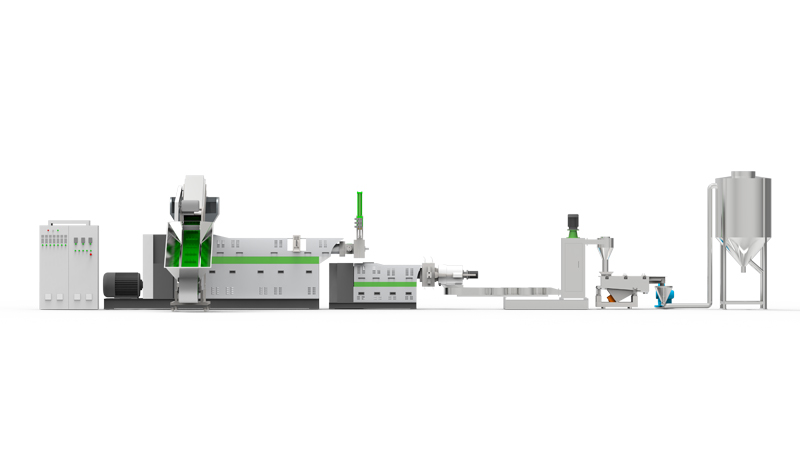

The power transmission system of the plastic conveyor is the core component to ensure its normal operation. This system includes key components such as motors, reducers, sprockets, and chains, which work together to ensure that the conveyor moves materials stably and efficiently.

Motor selection

Power requirements: The power requirements of the motor are determined based on the load of the conveyor, operating speed and specific application scenarios. Peak workloads and normal workloads need to be considered to ensure the motor has adequate power reserves.

Type selection: Conveyors usually use AC motors or DC motors. Choosing the appropriate motor type depends on the requirements of the application scenario. For example, for some occasions that require precise control, a DC motor may be preferred.

Protection level: According to the working environment of the conveyor, select a motor that meets dustproof, waterproof and other standards to improve the service life and reliability of the motor.

design of decelerator

Reduction ratio selection: The reducer is used to convert the high-speed, low-torque rotation output by the motor into the low-speed, high-torque rotation required by the conveyor. Reasonable selection of reduction ratio is the key to ensuring smooth operation of the conveyor under different loads.

Accuracy requirements: For some applications that require high-precision motion control, the manufacturing accuracy and transmission efficiency of the reducer will become important factors to consider during design.

Sprocket and chain design

Sprocket material: The sprocket is usually made of high-quality alloy steel or stainless steel to ensure that it has sufficient strength and wear resistance. The selection of materials needs to consider the characteristics of the conveyed materials to avoid affecting the transmission efficiency due to wear.

Chain type: According to the design requirements of the conveyor, different types of chains can be selected, such as roller chains, bent plate chains, etc., to adapt to different working environments and working conditions.

Chain Tension: Chain tension is very important for the proper operation of the transfer system. The chain tensioning method needs to be considered in the design to ensure that it does not become loose or overtightened during operation.

Power transmission efficiency optimization

Friction loss reduction: During the design process, materials with low friction coefficients should be considered to reduce friction losses in transmission and improve transmission efficiency.

Lubrication design: Choose appropriate lubrication methods and materials to ensure normal lubrication of chains and sprockets, reduce friction, and extend the service life of parts.

Copyright © Yuyao Lvdao Plastic and Rubber Machinery Co.,Ltd. Plastic Granulation Line Supplier 浙ICP备11026885号-3